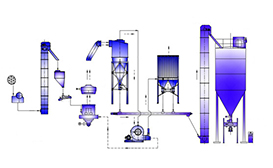

The monazite powder processing adopts the grinding method, and its production line equipment includes jaw crusher,

cone

crusher, Raymond mill (main part), bucket elevator, electromagnetic vibrating feeder, classifier, pipeline. The

specific

process flow of the device is as follows:

1. The crushing stage

First, the large amount of monazite extracted is initially crushed by a jaw crusher, and then sent to a cone crusher

for

further fine crushing. The reason why the two sections are broken is to achieve sufficient dissociation of the

useful

material of the ore. The milling stage provides better ore raw materials.

2. Screening stage

The crushed monazite material is not very uniform, and the mill has a specified feed size. In order to prevent the

bulk

material from entering the mill and causing adverse effects, the vibrating screen is generally used for screening

treatment to make the monazite mill. The powder index has increased significantly.

3. Grinding stage

Next, the sieved monazite scraps will be transported from the bottom up to the silo by the bucket elevator, and then

sent to the Raymond mill for deep grinding by the electromagnetic vibrating feeder.

4. Powder selection stage

Finally, the powdered monazite powder will be classified by the classifier. The unqualified fine powder will be sent

back to the main machine for re-grinding. The monazite powder meet the fineness requirements will enter the finished

silo through the pipeline device, and the powder tanker will be used uniformly. Pack it out.