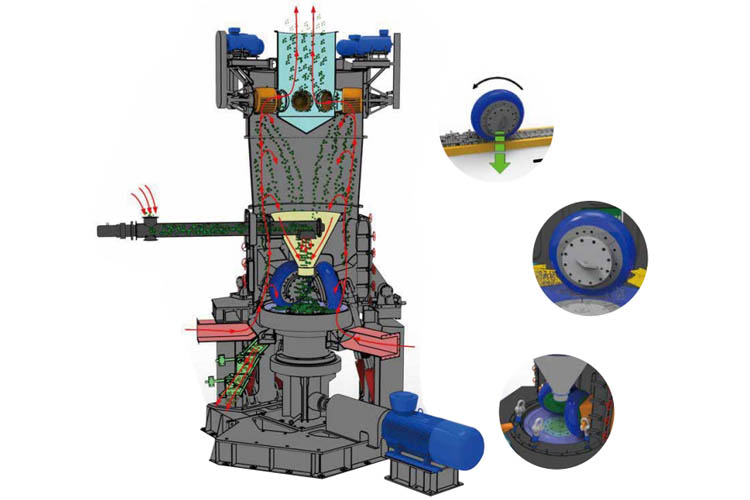

As a new type of ultrafine grinding equipment, the LUM ultrafine vertical mill integrates powder grinding, separation and transportation. With years’ experience in mill production, the LUM ultrafine vertical roller mill are designed by our company, basing on vertical mills, we introduce Taiwan’s grinding roller technology and Germany powder separating technology. As a professional medium and high-end processing equipment in plastic master batch, PVC, artificial stone, electric cable, non-woven fabrics and other industries,LUM Series LUM Ultrafine Vertical Mill is mainly used for the ultrafine grinding of calcite, marble, limestone, talc, dolomite, barite, kaolin, wollastonite, gypsum, feldspar, pyrophylite and other non-metallic mineral ores.

- Input Size: 0-20mm

- Output Size: 325-2500 mesh