The chemical principle

In air pollution control industry, power plant desulfurization is a hot

topic.

There are many different kinds of power plant desulfurization methods.

For most of the

popular

methods need to use limestone powder, the preparation of lime powder is very important.

Products recommended

Note:We can offer the whole lime stone powder making machines and provide limestone powder desulfurization preparation technology.

The process of desulfurization

The Production of Desulfurization Limestone Powder

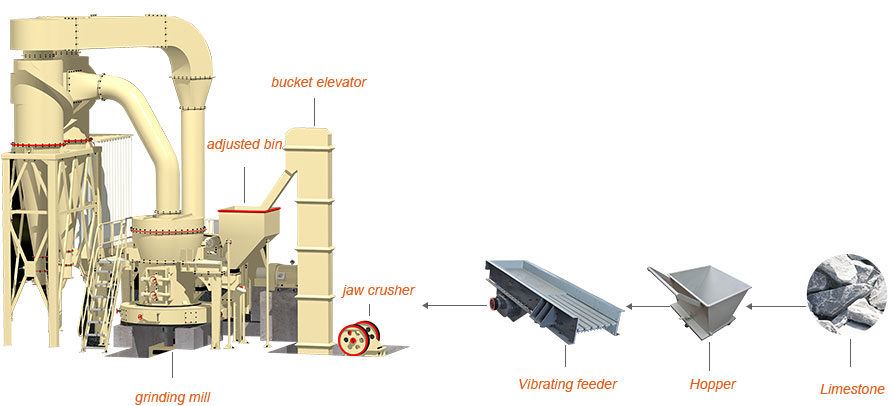

The bulk material is firstly sent to the jaw crusher and crushed into

desired granularity. And then material are fed into grinding mill by bucket elevator. The

grinded

powders, which rise with airflow of fan, are grades by collector.

The whole system running

under

the negative pressure condition, no dust generates, so as to meet the environment protection

standard.

The Instance Site OF Limestone Powder Desulfurization Process

Running instance:

A thermal power plant using limestone - gypsum wet

desulphurization

process (FGD), add water in limestone powder to be limestone slurry as the absorbent. This

process

is the most mature technology in the world, the most widely used in desulfurization process,

advantage lies in the sorbent utilization rate is as high as 90%, desulfurization efficiency

is more than 95%, and putting into operation rate is as high as 99%, suitable for large

capacity

units, can deal with all kinds of sulfur content coal.

Customer evaluation:

The desulfurization equipments bring us a revolutionary experience, high capacity, good

environmental protection and low power consumption. Compared with other local suppliers, our

energy consumption is the lowest, so we have great price-advantages. Thank you very much for

SBM!

Experts’ analysis:

As soon as MTW grinding mill was taken into market, it

has

been successfully used in power plants, steel desulfurization projects. Till now, it is one

of

the most cost-performance machines.

Limestone desulfurization case 1

Mill: 5 sets of MTW175, the whole unit rated power 390kw

Capacity:

70t/h

Raw material and fineness: limestone, 325mesh, D95

Limestone desulfurization case 1

Limestone desulfurization case 1

Limestone desulfurization case 2

Mill: 1 set of MTM160, the whole unit rated powder 282.5kw

Capacity:

11t/h

Raw material and final products:limestone, 250mesh,D95

Limestone desulfurization case 2

Limestone desulfurization case 2

Running instance:

Power plant using LIFAC dry fuel gas desulfurization technology, with limestone powder

as

SO2 absorption agent, desulfurization process is divided into two stages: furnace

desulfurization

and activation desulfurization in the vessel. Thus, combines the advantages of furnace

desulfurization

and spray drying desulfurization. The process is relatively simple, maintenance is

convenient,

and the desulfurization efficiency reaches 60% to 85%.

Customer evaluation:

After the investigation and comparison, I chose the SBM MTM160 grinding mill. The

quality

of the absorbent help me win a lot orders from many thermal power plants. Now the capacity

is

far from their demand, so I would like to build another plant in the next year.

Experts’ analysis:

MTM overpressure trapezium mill is updated and improved from the high pressure roller

mill,

it has five patents skills, such as trapezoidal working face, the flexible connection,

roller

linkage pressurization etc. Therefore, it has the good grinding effect, can improve the

fineness

of limestone powder and production, and is a very good choice for desulfurization agent

preparation.

Running instance:

A power plants using spray drying process of desulfurization (SDA semi-dry method),

with

limestone powder slurry as absorbent. Under ideal conditions of SDA process, the

desulfurization

efficiency can reach 80% - 90%, if using bag filter, the desulfurization efficiency can be

increased

by 10% - 15%. Its characteristic is that by-product is solid, no liquid waste.

Customer evaluation:

This several sets of vertical mill run stability, high output, low loss, and operation

simple.

We are very satisfied with the equipments. And after-sales service and free training is

particularly

great. Just a phone call, technical personnel will be rushed to the scene immediately to

satisfy

what you need. SBM is the best the enterprise which we have contacted with.

Experts’ analysis:

LM vertical grinding mill is another masterpiece of SBM

research and development team. It sets the crushing, drying, grinding, classification,

transmission

together, which is ideal equipment in the fields of thermal power plant desulfurization,

pulverized

coal preparation.

Limestone desulfurization case 3

Mill: 3 sets of LM170 Vertical Mill, the whole unit rated power 900kw

Capacity:

40TPH

Raw material and fineness: limestone 200 mesh, D80

Limestone desulfurization case 3

Limestone desulfurization case 3

The Advantages of SBM Mill for Lime Stone Powder

The traditional mechanism for lime stone powder has many disadvantages, large energy consumption, low production, complex process, bad controllability. To overcome this problem, SBM developped the MTM trapezium mill, MTW medium-speed milling machine and vertical roller mill. They bring a new revolution in the field of limestone powder production.

Integral drive-system

With this design, energy consumption is greatly reduced.

Volute design

Reducing energy loss, high efficiency

Unique plough design

Fission types, convenient for maintenance, wear resistant material, long life

Good appearance

Compact conformation, elegant appearance

High-performance powder concentrator design

Accurate and quick selection of powder

Arc air-duct

Reducing resistance, improving working effeciency

The Advantages of SBM Mill for Lime Stone Powder

The traditional mechanism for lime stone powder has many disadvantages, large energy consumption, low production, complex process, bad controllability. To overcome this problem, SBM developped the MTM trapezium mill, MTW medium-speed milling machine and vertical roller mill. They bring a new revolution in the field of limestone powder production.

Integral drive-system

With this design, energy consumption is greatly reduced.

Volute design

Reducing energy loss, high efficiency

Unique plough design

Fission types, convenient for maintenance, wear resistant material, long life

Good appearance

Compact conformation, elegant appearance

High-performance powder concentrator design

Accurate and quick selection of powder

Arc air-duct

Reducing resistance, improving working effeciency