Ground Calcium Carbonate(GCC) Grinding Technical

Ground Calcium Carbonate(GCC) is usually made by grinding natural carbonate minerals such as calcite, marble and limestone. It can be got by wet or dry process. Currently, dry process is popular at home.

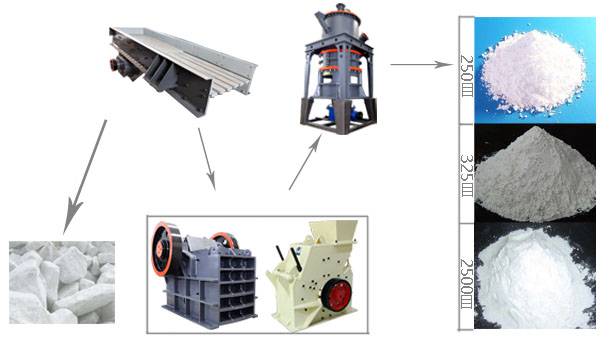

GCC Grinding Process

Crushing Stage

Big blocks of natural carbonate minerals like calcite, marble or limestone would be crushed into particles within 15mm-50mm --- the feeding size of grinding mills.

Grading Stage

The ground Ground Calcium Carbonate(GCC) with air flow would be graded by powder separator. After that, the unqualified powder would be sent back to the grinding cavity for another grinding.

Grinding Stage

The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding

cavity where the materials

would be ground into powder.

Usually, LM vertical grinding mill, MTW European grinding

mill and MTM over-pressure

trapezoidal grinding mill are often used for fine powder processing while LUM ultrafine

vertical grinding mill and

SCM ultrafine grinding mill are often used for ultrafine grinding.

Powder Collecting Stage

With air flow, powder meeting the standard enters into the powder collecting system along the pipe. The finished powder products are sent to finished product warehouse by conveyor and packed by powder filling tanker and automatic pack machine.

How to match a calcium carbonate plant

Calcium carbonate plant can produce calcium carbonate powder with different fineness between 80-2500 mesh,Calcium carbonate plant need to crushing equipment, milling equipment and some corresponding mining equipment work together, the way to match jaw crusher, hammer crusher,MTM series trapezium mill、modification machine, powder packaging machine, belt conveyor, vibrating feeder, etc.