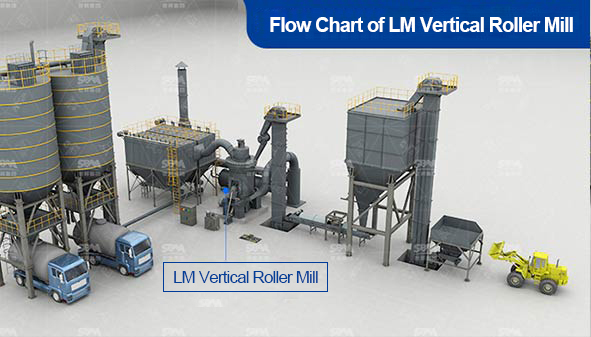

POWER PLANT DESULFURIZATION GRINDING PROCESS

Crushing stage

After crushing limestone with high calcium content and meets the requirements for entering the mill.

Grinding stage

The feeder continuously and evenly feed suitable raw materials into the main grinding chamber, and the fine powder after being ground rises to the classifier for classification under the action of the fan airflow, and the fine powder of qualified fineness enters the collection stage through the air outlet pipeline.

Collection stage

The dust gas from the grind enters the cyclone collector through the main mill air outlet pipeline, and most of the finished fine powder is separated and collected under the action of centrifugal force, and transported to the finished product conveying stage together through the screw conveyor. At the same time, the exhaust gas is discharged into clean gas through the pulse dust collector.

Conveying stage

Screw conveyor sent the finished ore powder into the bucket elevator, and then enters the slender deep silo finished product tank. The dust gas in the tank is collected by the dust collector top of the tank and the finished product is stored in the finished tank and discharged the clean gas.

Desulfurization stage

The finished stone powder is transported to the absorption tower after pulping. The slurry in the absorption tower is pumped to the spray device by circulation pump. It reacts chemically with SO2 entering the absorption tower to achieve the purpose of desulfurization.