Vertical roller mill stone powder production decline

Vertical roller mill stone powder production decline

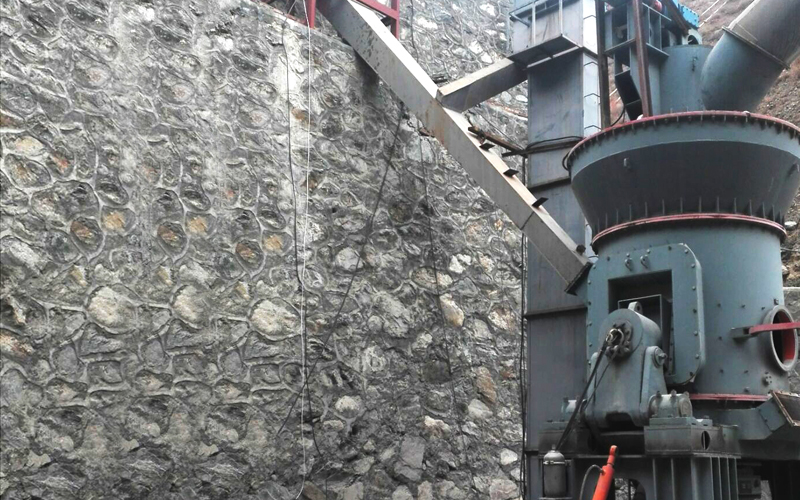

The vertical roller mill is a kind of mining machinery equipment which is more commonly used. The machine is simple and easy to operate, with high production efficiency and low price. It is very popular among the users. However, if the vertical roller mill is used for a long time, there will always be one or the other. The situation, this is not a recent user consultation, what is the reason for the sudden decrease in the amount of powder in the vertical roller mill? We also found the professional and technical personnel of our company to answer the questions for the majority of users.

1. The material is too hot, resulting in a decrease in the output of the vertical roller mill

The over-current of materials is the main reason for the decrease of stone powder production. It not only increases the difficulty of grinding, but also the finished product is easy to block the powder discharge channel of the vertical roller mill, which makes the mill work unsmooth, causing a large amount of stone powder to clog, resulting in a decline in finished product output.

2. Equipment wear is serious

The vertical roller mill mainly relies on the grinding of the grinding ring and the grinding roller to realize the milling. If the two parts are worn too much, the material will not grind to the desired fineness of the user and will continue to circulate in the grinding chamber. Production has fallen.

3. Too much or too little material

When the vertical roller mill equipment is working, the feed rate should be controlled well, not too fast or too slow. Excessive material in the grinding chamber affects the performance of the equipment. Too little grinding machine idles and the output naturally decreases.

4. Other parts and equipment are damaged

The damage of any one part will have a great impact on the final output. For example, important parts such as analyzers and fans should be inspected on time, and problems should be solved in time to ensure the normal operation of the equipment.