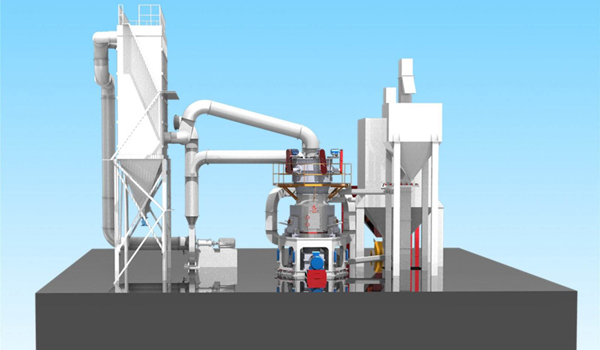

Vertical roller mill grinding machine fault handling and maintenance method

Vertical roller mill grinding machine fault handling and maintenance method

The clogging of the vertical roller mill is one of the common faults in the use of the mill. It may be a problem in the design of the organic tool, but it is more caused by improper operation. The feed rate is too fast and the load is increased, causing blockage. During the feeding process, always pay attention to the large deflection angle of the ammeter pointer. If the rated current is exceeded, it indicates that the motor is overloaded and overloaded for a long time, which will burn the motor. In this case, the door should be immediately reduced or closed, and the way of feeding can be changed. The feeder is controlled to increase the amount of feed. There are two types of feeders: manual and automatic. Users should select the appropriate feeder according to the actual situation. Due to the high speed of the mill, the load is large, and the load is highly volatile. Therefore, the current when the mill is working is generally controlled at about 85% of the rated current. If the discharge pipe is not smooth or the feed is too fast, the air outlet of the mill will be blocked; improper matching with the conveying equipment will cause the wind of the discharge pipe to be weakened or blocked after no wind. After the fault is detected, the conveying equipment whose delivery port is not matched shall be cleared first, and the feeding amount shall be adjusted to make the equipment operate normally.

After the installation and commissioning of the vertical roller mill grinding machine is completed, before the operator takes over the production operation, please read the product manual carefully, understand the structural principle of the milling machine, familiar with the performance and operation rules of the milling machine, and operate in strict accordance with the operating procedures. At the same time, according to the operating procedures and precautions, patrol inspection. Keep the following work in mind while operating in strict accordance with the operating procedures:

- (1) The motor of the vertical roller mill has been sealed before leaving the factory, the coupling has been corrected, please do not loosen;

- (2) Timing cleaning of iron impurities on the permanent magnet plate of the permanent magnet cylinder and the mill feeder;

- (3) Regularly check the fineness of the finished product;

- (4) The vertical roller mill regularly cleans or replaces the dust collector bag (make sure the bag is breathable), and regularly check the working condition of the solenoid valve.

- (5) Regularly check the wear of the wearing parts of the mill to see if it is normal wear and tear;

- (6) Always pay attention to the vibration of the mill;

- (7) When the hammer of the vertical roller mill is seriously worn and needs to be replaced, it is necessary to pay attention to ensure the weight difference between the two hammers on the two opposite (1800 direction) hammer pins is ≤1g and two relatives ( 1800 direction) the total weight difference of the hammer on the hammer pin shaft ≤ 2g;

- (8) When the vertical roller mill screen wears severely needs to be replaced, it is necessary to pay attention to whether the flatness of the new screen and the size of the screen are reasonable, whether the installation is in place, and the installation is so that the screen surface is facing inward;

- (9) The opening degree of the impeller feeder damper should be adjusted properly;

- (10) If it is found that the mill has large vibration and high noise, it should be stopped immediately;

- (11) After the 40-hour operation of the spindle bearing, 80 grams of grease should be added, but only 60%. After 1800 hours of operation, the bearing cover should be removed and all used grease should be replaced. When replacing the fresh grease, add grease to the area around the roller and the bearing ring, and add 1/3 to 1/2 of the grease to the bottom case. Never add too much grease.

- (12) When it is found that the output of the mill is suddenly decreased, in addition to the factors of raw materials, it is important to check whether the air supply door is in place, whether the pipeline is leaking, whether the pulse bag is blocked, whether the solenoid valve or the fan is working normally.