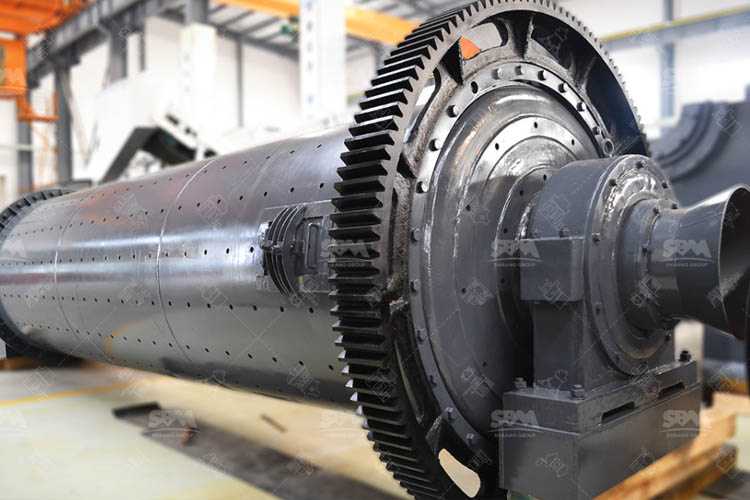

Ball Mill for Cement Grinding in Ghana

Ball Mill in Cement Grinding Plant

Ball mills are commonly used for cement grinding in Ghana and other parts of the world. Cement grinding is the process of grinding clinker (the main component of cement) and other additives to produce a fine powder that can be used to produce cement.

The ball mill is a rotating cylindrical drum that contains steel balls that grind the clinker and other materials in the drum. The rotation of the drum causes the steel balls to cascade, grinding the clinker and other materials to a fine powder.

In Ghana, ball mills are commonly used for cement grinding due to their efficiency and reliability. The grinding process is usually carried out in two or three chambers, with different size steel balls used in each chamber to produce different particle sizes.

The first chamber of the ball mill is typically used for coarse grinding, with larger steel balls used to grind the clinker. The second chamber is used for fine grinding, with smaller steel balls used to grind the finer particles. Some ball mills also have a third chamber, which is used for ultra-fine grinding.

The efficiency of the ball mill for cement grinding can be improved by using high-quality grinding media, such as high-chromium steel balls or ceramic balls. Additionally, the ball mill can be optimized by adjusting the operating parameters, such as the speed of rotation and the amount of material in the mill.

6 Advantages of Ball Mill

There are several advantages of using a ball mill for cement grinding:

Efficient grinding: Ball mills are known for their high grinding efficiency, which results in a fine and uniform grind of the material. This is achieved by the continuous cascading of the grinding media inside the mill.

Versatility: Ball mills can be used for both wet and dry grinding, and can be adapted to handle a wide range of materials. This makes them ideal for use in the cement industry, where a variety of raw materials are used.

Low energy consumption: Ball mill is generally more energy-efficient than other grinding technologies, such as vertical roller mills and roller presses. This means that less energy is required to grind the same amount of material, which can lead to significant cost savings.

Simple operation: Ball mill is relatively simple to operate and maintain, which makes them a popular choice for cement manufacturers. They require minimal maintenance and can be easily integrated into existing cement plants.

Consistent quality: Ball mills produce a consistent and uniform product, which is essential for the production of high-quality cement. This is achieved by controlling the size and composition of the grinding media and the speed of the mill.

Flexibility: Ball mill can be used for both large-scale and small-scale cement production, making them a flexible and adaptable solution for a wide range of cement plants.

In summary, ball mill is commonly used for cement grinding in Ghana and are an important part of the cement manufacturing process. The optimization of the ball mill operation and the quality of the cement produced are key factors in ensuring the efficiency and profitability of cement production in Ghana.