As a time-honored inorganic chemical raw material, quick lime is produced by high-temperature calcination of limestone. It features strong alkalinity, high activity and excellent water absorption. With physical properties such as high melting point and good fire resistance, it boasts stable chemical properties and can react with various substances, serving as an indispensable basic material in construction, metallurgy, environmental protection, agriculture and other fields.

With its strong alkalinity, high reactivity, water absorption and adhesiveness, quick lime has become an indispensable basic raw material in modern industry. Its applications span key pillar industries of the national economy such as construction, metallurgy, chemical engineering, environmental protection and agriculture, earning it the reputation of "the grain of industry".

Metal Smelting Field

Environmental Protection Field

Building Materials Field

Agricultural Field

Chemical Industry Field

Other Fields

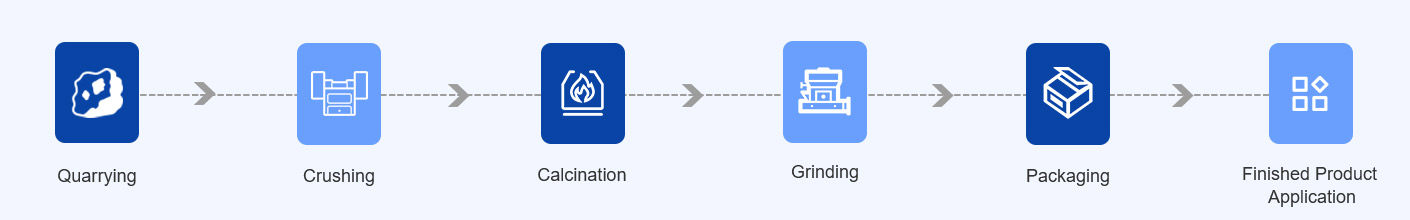

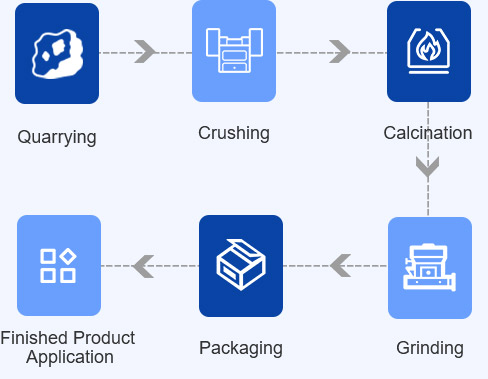

The industrial preparation of quick lime centers on limestone calcination, involving multiple processes such as quarrying, crushing, calcination, grinding and packaging.

Currently, the quick lime industry is transforming from "single processing" to "full-chain collaboration". The advancements in intelligent mining and raw material pretreatment technology in upstream mines, the upgrading of calcination and grinding equipment in the midstream, the continuous expansion of downstream application scenarios, supplemented by the green transformation of the energy support system, together constitute the core competitiveness of the quick lime industrial chain.

Upstream

Raw Material Pretreatment

Limestone is crushed and screened to ensure uniform particle size, laying the foundation for efficient calcination.

Key Process

Grinding Preparation

Lumpy quick lime undergoes precise grinding to be transformed into powders with different fineness and activity levels, a critical step to unleash its application value.

Downstream

Expansion of Application Scenarios

In addition to traditional applications, new products like soil remediation agents and hazardous waste solidifiers have been developed, and emerging application scenarios such as power battery materials have been expanded.

Auxiliary Support

Clean Coal Powder Preparation System

A coal powder preparation unit specially designed for lime kilns, serving as the core energy supply for the calcination process.

Among these, the preparation focuses on two critical processes: calcination and grinding. The grinding process not only determines the particle size distribution, specific surface area, and reactivity of the product but also directly impacts energy consumption, efficiency, and end-use performance. Traditional grinding methods often face challenges such as low efficiency, high energy consumption, uneven particle size, and difficulty in pollution control.

As a pioneer in the industrial grinding sector, SBM has built an intelligent full-process equipment system covering crushing, grinding, classification and dust collection, relying on nearly four decades of technological accumulation. It provides customized solutions for the quick lime industrial chain.

Process Flow of MTW European trapezium mill

Quick lime is uniformly and continuously fed into the main mill chamber by a variable-frequency belt feeder for grinding. The ground quick lime powder is conveyed by fan airflow to a classifier for sizing. Under the action of the analyzer, materials failing to meet the fineness requirement fall back into the mill chamber for re-grinding. The powders are discharged as finished products via the unloading device.

Process Flow of LM vertical mill

Quick lime is metered by a hopper and a quantitative feeder, then conveyed by a belt conveyor to an elevator. Then fed into an LM vertical mill through air-locking feeding equipment such as conveying devices for grinding. The ground quick lime powder is sized by a classifier.

Process Flow of LUM ultrafine vertical mill

Quicklime falls into the center of the grinding disc through the screw feeder and is rolled by the grinding roller. The crushed quicklime continues to move towards the edge of the grinding disc, and is carried into the powder separator by the air flow entering from the air inlet for classification. The quicklime powder discharged after collection is the finished powder.

Process Flow of LM vertical coal mill

Raw coal is screened and dedusted, the coal is fed into LM vertical coal mill by a coal feeder, where it is dried and ground with hot air introduced from a hot air furnace. The coal powder is separated by a classifier along with the airflow. When preparing high-volatile coal powder, a nitrogen protection system and CO2 fire extinguishing system are activated in interlock control to ensure safe production.