Limestone, commonly referred to as lime rock, is a carbonate rock primarily composed of calcite. It may sometimes contain dolomite, clay minerals, and detrital minerals, exhibiting various colors such as gray, gray-white, gray-black, yellow, light red, and brown-red. Its hardness is generally low, and it reacts vigorously with dilute hydrochloric acid, producing bubbles. It is classified as a sedimentary rock based on its origin.

Limestone is a common non-metallic mineral and a valuable resource with a wide range of applications. After being processed by a grinding mill, limestone can be applied in various fields, yielding considerable economic benefits. It is a primary raw material for manufacturing cement, lime, and calcium carbide, and is also widely used in industries such as metallurgy, chemicals, building materials, and power plant desulfurization.

With the tightening of environmental protection policies, the lime deep processing industry has received increased attention in recent years. In addition to traditional applications in construction, metallurgy, and agriculture, lime is also increasingly used in environmental protection fields such as wastewater treatment and flue gas desulfurization. Lime deep processing mainly refers to the processing applications from limestone to lime. In simple terms, limestone is calcined to produce lime, which is primarily composed of calcium oxide also known as quicklime. Quicklime, when hydrated, becomes slaked lime, which is primarily composed of calcium hydroxide.

Production of calcium oxide:

Calcium oxide is obtained by high-temperature calcination of limestone, commonly known as quicklime. Calcium oxide has various industrial applicationssuch as being used as an alkaline oxide in environmental protection fields like industrial wastewater treatment, waste incineration, and flue gas desulfurization.

Production of calcium hydroxide:

Calcium hydroxide is formed by the dissolution of calcium oxide in water, commonly known as slaked lime or hydrated lime. Calcium hydroxide can be used as an acidity regulator in food, providing buffering, neutralizing, and solidifying effects. It is also widely used in the production of calcium supplements, pharmaceuticals, the synthesis of food additives, and high-tech biomaterials.

Rubber industry:

In the rubber industry, the addition of calcium carbonate can improve the dispersion, vulcanization elongation, and tear resistance of rubber products. The incorporation of calcium carbonate can enhance the processing and physical properties of rubber.

Plastic industry:

Calcium carbonate can increase the volume of plastics, reduce product costs, and improve the dimensional stability, hardness, and rigidity of plastics. It also enhances the processing performance, heat resistance, and light scattering properties of plastics.

Other fields:

Limestone can also be used to produce nano calcium carbonate, a functional inorganic filler with a particle size of 1-100 nm, widely applied in rubber, plastics, papermaking, inks, coatings, sealants and adhesives, pharmaceuticals, toothpaste, and food. Additionally, limestone itself, as a carbonate rock, has fundamental applications in construction and road building.

The selected limestone is sent to an environmentally friendly lime kiln for high-temperature calcination, transforming it into quicklime.

Quicklime can be directly crushed using a MTW trapezium mill or LM vertical mill, processing it from lump lime into powdered lime, which can be supplied directly to the market.

Quicklime can also undergo further deep processing by being sent to the calcium hydroxide production line, where it is transformed into slaked lime after five stages of slaking (1 stage pre-hydration - 3 stages homogenization - 1 stage pulverization).

The well-digested slaked lime can be directly screened using a classifier, and the collected product is high-quality calcium hydroxide, while excess residue is discharged.

The slaked lime can also be ground using a MTW trapezium mill or LM vertical mill. After achieving the required fineness, it is classified using a classifier and collected in a dust collector, resulting in ordinary calcium hydroxide products.

LM VERTICAL ROLLER MILL

MTW EUROPEAN TRAPEZIUM MILL

LUM ULTRAFINE VERTICAL MILL

SCM ULTRAFINE GRINDING MILL

Capacity: 10-170T/H

New grinding device

Fineness: 0.84-0.037mm

Drying and grinding two-in-one

Performance Advantages:

Automated electronic control system

Capacity: 10-170T/H

Fineness: 0.84-0.037mm

Performance Advantages:

New grinding device

Drying and grinding two-in-one

Automated electronic control system

Capacity: 3-60T/H

Patented product

Fineness: 1.6-0.045mm

Thin oil lubrication system

Performance Advantages:

Energy saving, environmentally friendly

Capacity: 3-60T/H

Fineness: 1.6-0.045mm

Performance Advantages:

Patented product

Thin oil lubrication system

Energy saving, environmentally friendly

Capacity: 3-15T/H

Higher yield, better quality

Fineness: 325-2500mesh

Safe, reliable, stable operation

Performance Advantages:

Multi-head powder selection, more economical

Capacity: 3-15T/H

Fineness: 325-2500mesh

Performance Advantages:

Higher yield, better quality

Safe, reliable, stable operation

Multi-head powder selection, more economical

Capacity: 500-25000KGPH

High fineness

Fineness: 325-3250mesh

High efficiency and low loss

Performance Advantages:

Stable, reliable, environmentally friendly

Capacity: 500-25000KGPH

Fineness: 325-3250mesh

Performance Advantages:

High fineness

High efficiency and low loss

Stable, reliable, environmentally friendly

As a provider of comprehensive grinding equipment solutions, SBM has been committed to developing more efficient, energy-saving, and environmentally friendly grinding equipment. With nearly 40 years of experience in the design, research, and manufacturing of grinding mills, it has launched different models of grinding mills to meet the preparation of limestone powder with various particle sizes. Known for low construction cost and green environmental protection, it is an ideal choice for customers.

Finesse: 200 mesh D65 Application:Construction Equipment: LM Vertical Mill

Finesse: 250mesh D90 Application:Calcium supplements Equipment: MTW European Trapezium Grinding Mill

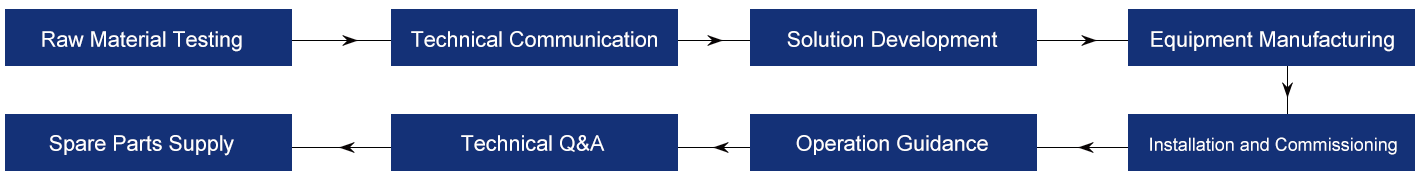

SBM, with a complete R&D system, large production base, advanced product production lines, and high-quality market service system, has provided non-metallic mineral powder processing solutions for numerous enterprises.

Choosing SBM is not just selecting a piece of equipment, but also choosing a reliable industrial partner.

SBM promises: In the future, we will use innovation as our engine and customer value as our core, continuously providing more efficient, cleaner, and smarter solutions for the global industrial grinding industry, together writing a new chapter in the efficient use of resources and sustainable development!