Various problem solutions during the use of Raymond Mill

Various problem solutions during the use of Raymond Mill

First. How should the material of the return air belt of the mill be treated?

The circulating wind design adopted by Raymond Mills sometimes has the phenomenon of return air belt materials. How should it be solved?

There are two reasons for the return air belt material:

The material of the first powder collector is too much, and the material of the discharge port is too heavy. The material inside the dust collector is too much. The return air takes the material away and enters the working cavity to re-grind, which will seriously affect the production of Raymond Mill.

The lower pressure valve at the position of the second discharge port can not be lifted up and can only be pressed downwards. When the return air is lifted up once, the material inside the dust collector is taken away into the working chamber.

The Raymond Mill uses a roller roll for control, which controls the fineness and output through the air volume adjustment of the analyzer and the damper. The air volume is large, the fineness is coarse, and the output is high; the air volume is small, the fineness is fine, and the output is low. The analyzer has high speed, high fineness and low output; the analyzer has low speed, fineness and high output. Please consult a professional manufacturer about the problems encountered by Raymond Mill in the daily operation.

Second, what is the cause of the Raymond grinding machine phenomenon?

The phenomenon of Raymond's grinding machine is caused by blockage in many cases, and the mill cannot operate normally. If the blockage is severe, the motor will be burned, which will have a great impact on production. In order to avoid the phenomenon of Raymond mill crash, we must pay attention to the following problems during normal operation:

1. In the normal work of the mill, it can't be suddenly fed too much, and the feed is too little. The uniform feeding mill is always grinding, and the materials are constantly going out;

2. The grinding machine installation circuit must be equipped with a power distribution cabinet to ensure the normal operation of the circuit;

3. The lower pressure valve at the position of the discharge port cannot be lifted up. When the air is lifted up, the material inside the dust collector will be brought into the working chamber. This is also the reason that the mill is easily blocked and not discharged.

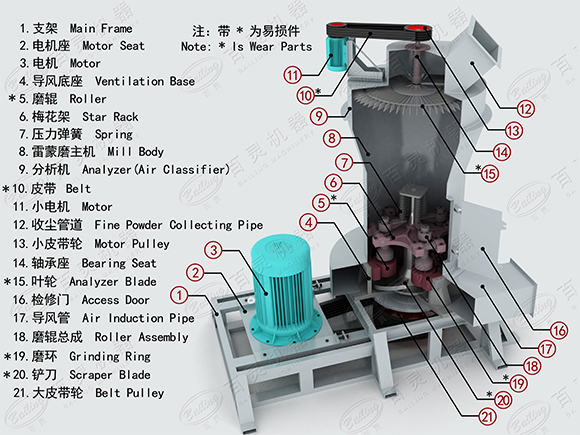

When the Raymond mill is in normal operation, the feed port draws air into the inside, and the material is continuously stopped. The Raymond mill uses a suspension roller to compact the air to achieve the pulverization effect, and the powder is cut once at a time, and the fineness is adjusted between 80-400 mesh. The link sealing requirements of Raymond mill pipe are very strict, there is no place for air leakage, and the sealed type environmentally friendly grinding equipment.

Third, Raymond mill does not produce no output, what is going on?

Raymond mill pulverizes the material by the principle of suspension roller compaction and air separation, and the fineness is adjusted by the speed and air volume of the analyzer. Raymond mill in the normal production, suddenly do not discharge what should be done? The following small series on the production of Raymond mill does not produce problems, a detailed analysis.

Raymond mills use a circulating air design, not a direct current. Therefore, the analysis machine is to the pipe of the dust collector, and the flange of the pipe connecting device of the dust collector to the fan must be sealed very strictly, and there must be no air leakage. The weight of the lower pressure valve at the position of the discharge port of the powder collector must be reasonable and can be uniformly discharged. If it is manually controlled, the boot must be pressed down for about 5 minutes. When there is material in the powder collector, slowly lift it up. The dust bag must be blown when it is working in Raymond mill. The bag must be kept breathable. If it is not breathable, the Raymond mill will be shocked. Raymond mill suddenly did not discharge, first of all, the lower pressure valve of the powder collector was lifted up, and it would not be discharged for 5 minutes. There is also a sudden loosening of the Raymond mill's damper, which suddenly shuts down.