Quartz Processing Techniques and End-Use Applications

Quartz is a common mineral primarily composed of silicon dioxide (SiO2). It is the second most abundant mineral in Earth's continental crust, and its crystalline structure makes it a key component of many rocks such as granite, sandstone, and quartzite. Quartz is known for its durability, chemical resistance, and piezoelectric properties, making it useful in various industries such as electronics, glass production, and construction.

How to Process Quartz?

Processing quartz involves several steps:

1. Extraction: Quartz is often extracted from open-pit mines. The mining process involves removing overburden, drilling, blasting, and hauling the quartz-bearing rocks to the processing plant.

2. Crushing: The extracted quartz rocks are crushed into smaller pieces, usually using jaw crushers, impact crushers, or cone crushers.

3. Grinding: The crushed quartz is further ground into finer particles using ball mills, ultrafine vertical mill, or other grinding equipment. This step can be repeated multiple times to achieve the desired particle size.

4. Magnetic separation: Impurities like iron and other magnetic minerals are removed from the ground quartz using magnetic separators.

5. Acid leaching: The ground quartz may undergo acid leaching to remove impurities like aluminum, iron, and titanium, which can affect the final product quality. Hydrofluoric acid, sulfuric acid, or a combination of acids can be used for this purpose.

6. Drying: The purified quartz is dried using rotary dryers or fluid bed dryers to remove any residual moisture.

7. Screening: The dried quartz is screened to separate it into different size fractions based on the requirements of the end-use applications.

8. Packaging and storage: The final processed quartz is packaged and stored in bags or bulk containers, ready for shipment to customers.

In addition to the above steps, some quartz processing plants may also include additional steps, such as flotation, gravity separation, or electrostatic separation, depending on the specific quality and end-use requirements of the quartz.

Overall, the processing of quartz involves a series of complex and rigorous steps to ensure the production of high-quality quartz powder suitable for various applications.

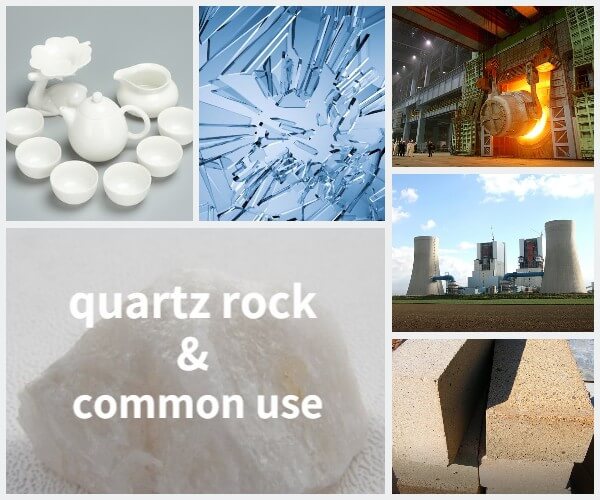

Quartz Applications & Uses In Different Industries

Quartz is a versatile mineral with a wide range of applications due to its unique properties. Here are some of the most common applications of quartz:

1. Construction: Quartz is used in the construction industry as a raw material in the production of concrete, mortar, and other construction materials. It is also used as a decorative stone in buildings and monuments.

2. Electronics: Quartz is widely used in the electronics industry due to its piezoelectric properties. It is used to produce oscillators, filters, and resonators for timing and frequency control applications.

3. Glass production: Quartz is a key component in the production of glass. It is used as a raw material to make glass containers, optical glass, and other specialty glass products.

4. Jewelry: Quartz is a popular gemstone used in jewelry making. It is available in a wide range of colors and varieties, including amethyst, citrine, and rose quartz.

5. Solar panels: Quartz is used in the production of solar panels as a raw material in the manufacturing of silicon wafers.

6. Filtration: Quartz sand is used in water filtration systems to remove impurities and contaminants.

7. Paints and coatings: Quartz powder is used as a filler in paints, coatings, and other composite materials.

8. Chemical industry: Quartz is used in the chemical industry as a raw material in the production of silicones, silicon carbide, and other chemical compounds.

Overall, the unique properties of quartz make it a valuable mineral with a wide range of applications in various industries.