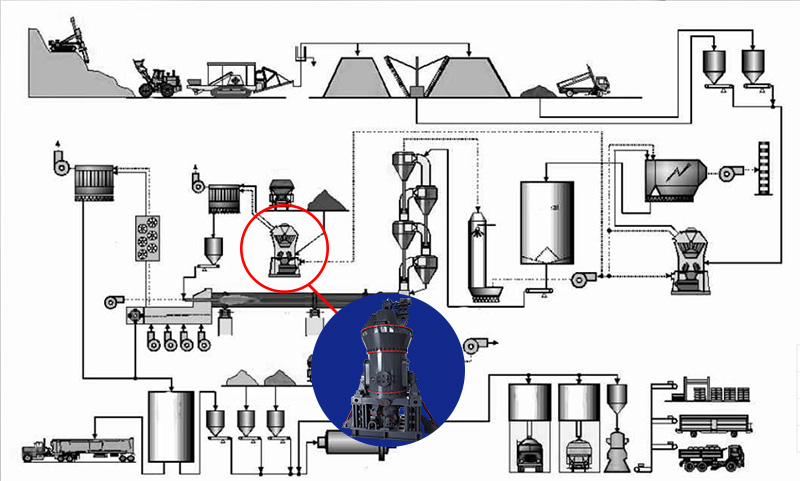

SBM’s Cement & Desulfurization System

With the country’s control on the cement production capacity, some cement companies, apart from searching merger & reorganization, start to march into the aggregate, new materials and non-metallic mineral fields and even extend their hands to the financial industry and real estate markets. It has become a trend for cement enterprises to explore the new industries.

SBM has been adhering to "What market needs is what we set about manufacturing." SBM is committed to the transformation & development of cement industry and constantly improve large-scale gravel production lines of general contracting projects. SBM starts to carry out development strategy of "diversified market share, focusing on a single area" by exploring new markets and throwing attention to mining, energy and other industries.

SBM, began its development from equipment production of cement industry, is able to undertake aggregate production project with daily capacity 1000-20000 tons. SBM offers a turnkey project from the design, civil engineering, equipment selection and installation and provides a full set of equipment and spare parts. According to the needs of different customers, SBM customizes production lines by analyzing material characteristics, production capacity, ore abrasiveness, site size, investment cost accounting and other aspects to make customers easier to configure products and to meet the majority of customer demands. And in terms of the cement industry’s demand for limestone, SBM launched special limestone crusher, slaked lime impact crusher, quick lime impact crusher, limestone crusher to elevate productivity and reduce abrasion on wearable parts caused by limestone.

Given potential market demand for desulphurized limestone in Xinjian, SBM has developed some necessary crushers used in desulfurization system including the special desulfurization crusher, special limestone desulfurization crusher, slaked lime desulfurization crusher, which are popular among desulfurization systems of fire power plants. The limestone desulfurization equipment got approval when it was put into use in the CNPC Xinjiang Huanneng Project in November 2010. The project mainly used the complete set of vibrating feeder and limestone-for-desulfurization crusher. During one-year use, SBM equipment performed well and attached the expectations perfectly. Considering that Xinjiang is abundant in calcite, SBM put special calcite crusher, calcite one-stage crusher, calcium carbide crusher, carbide slug crusher, ethyne calcite crusher into market to accelerate economic growth in Xinjiang regions.

Meanwhile, for demand of coal industry and its own advantages, SBM developed raw coal crusher, clean coal crusher and coal gangue crusher to help coal mining.

SBM Chairman expressed “wherever our machines used, SBM is always making efforts to do the best.”Under leadership of chairman, SBM is analyzing market demands and improving production technology. SBM has built an industry benchmark in multiple fields.