Empowering High-Quality Growth, Driving Green Upgrading — SBM Complete Grinding Solution for Activated Carbon

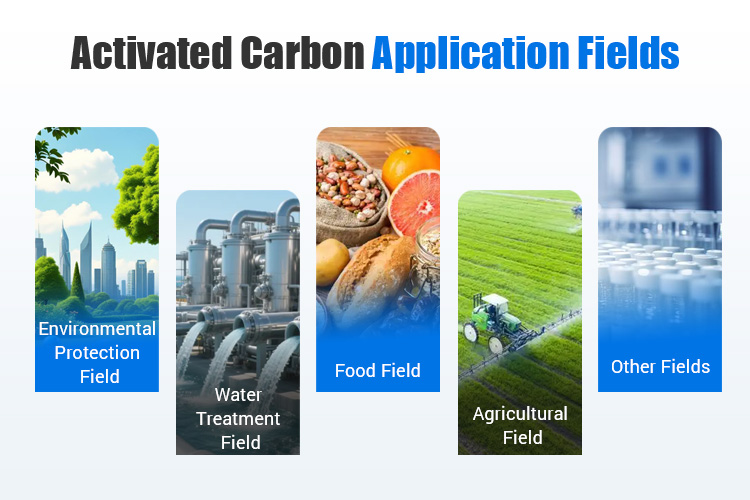

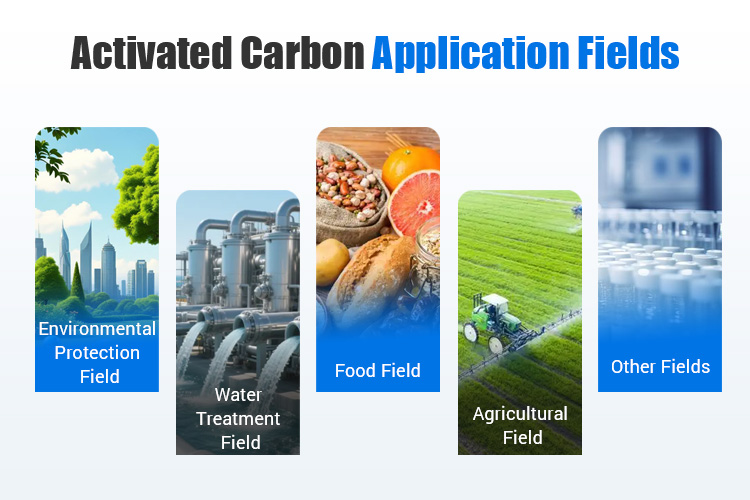

Against the backdrop of the accelerated development of the global environmental protection industry, activated carbon is ushering in unprecedented development opportunities. With continuous policy intensification, the rigid demand for high-performance activated carbon in VOCs abatement and advanced wastewater treatment has been strongly driven across industries such as printing and dyeing, chemical engineering, pharmaceutical manufacturing, petrochemicals and coating.

Meanwhile, its application scenarios are rapidly expanding to new energy, high-end food and beverage, pharmaceutical purification and other fields, with ever-increasing requirements for the performance and quality of activated carbon.

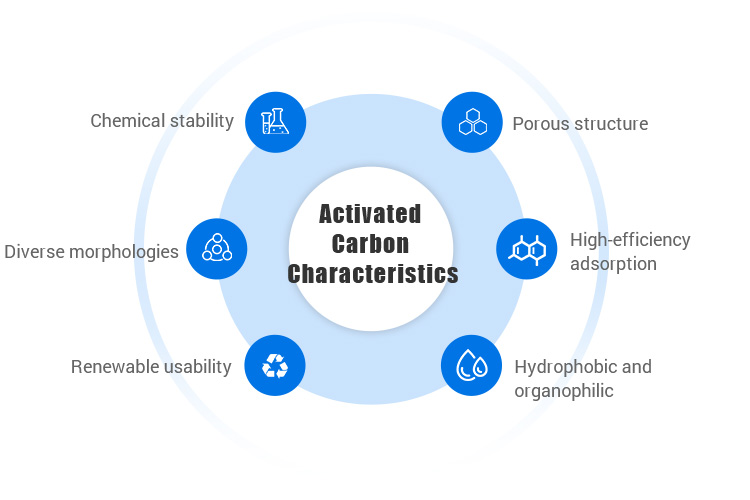

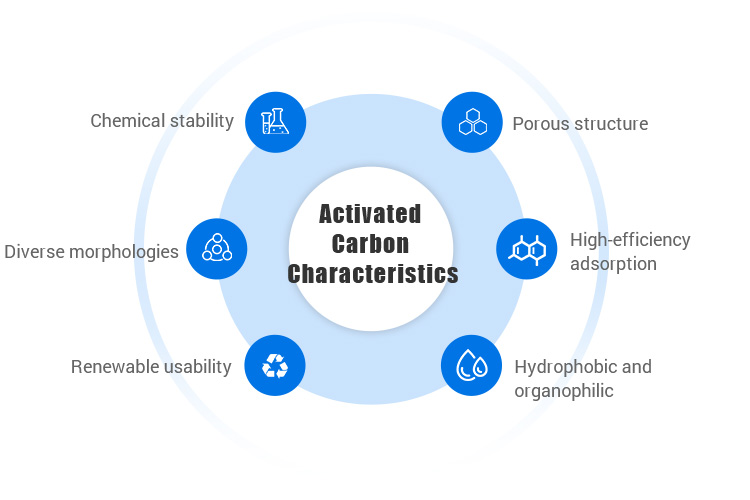

Activated carbon is a porous adsorptive material with a well-developed pore structure and high specific surface area, which is manufactured from raw materials such as coal, wood, fruit shells and synthetic resins via high-temperature thermal treatment processes including carbonization and activation.

Classified by raw material source, activated carbon is mainly divided into four categories: coal-based, wood-based (including coconut shell, fruit shell and wood chip), pitch-based and synthetic resin-based. Among them, coal-based and wood-based activated carbon dominate the market due to their easy raw material availability, stable performance and controllable cost.

Technology Empowered, Scenario-Adapted Grinding Solutions

SBM has an in-depth insight into the raw material characteristics and process requirements of different types of activated carbon, optimizes the grinding process and equipment configuration in a targeted manner, and creates a full-process solution that can be rapidly implemented and covers all production scenarios. Through precise process design, rational equipment selection and an intelligent control system, it fully achieves the efficient, stable and green production of activated carbon powder.

Preparation Process of Coal-Based Activated Carbon

The preparation process of coal-based activated carbon includes raw material pretreatment, batching, carbonization, activation, post-treatment and optional modification treatment.

With scenario adaptation, cost reduction & efficiency improvement, and green compliance as its core principles, SBM relies on two core grinding machine series — LM and MTW, and leverages nearly 40 years of global project experience to deeply cultivate application scenarios in the activated carbon industry. Through customized solutions for the LM and MTW series grinding machines, it provides stable and reliable grinding equipment support for the industry.

Product Advantages

Integrates crushing, milling, drying, powder classification and conveying into a single unit.

Adopts a special roller and grinding disc structure design; the grinding rollers are equipped with a hydraulic automatic pressure device, featuring a larger grinding area and high milling efficiency.

Equipped with an automatic control system, enabling simple and flexible operation and reducing operation and maintenance costs.

Operates under full sealing and negative pressure conditions, with no dust overflow.

Product Advantages

Curved blade design expands the material grinding contact area and boosts milling efficiency.

Integrated bevel gear drive and resistance-free air inlet volute design ensure better material fluidity and lower energy consumption.

Low resistance leads to low oil temperature, with an oil change interval of up to 4 months and reduced maintenance frequency.

Globally Verified, Winning Customers' Trust with Tailored Solutions.

The equipment of SBM is exported to more than 180 countries and regions worldwide. In the activated carbon sector, our solutions have been applied across multiple sub-scenarios, all achieving the core goals of superior quality compliance, enhanced operational efficiency and environmental regulatory conformity. The stable performance of our equipment and the efficiency of our service response have earned high recognition from customers.

Meanwhile, its application scenarios are rapidly expanding to new energy, high-end food and beverage, pharmaceutical purification and other fields, with ever-increasing requirements for the performance and quality of activated carbon.

Activated carbon is a porous adsorptive material with a well-developed pore structure and high specific surface area, which is manufactured from raw materials such as coal, wood, fruit shells and synthetic resins via high-temperature thermal treatment processes including carbonization and activation.

Classified by raw material source, activated carbon is mainly divided into four categories: coal-based, wood-based (including coconut shell, fruit shell and wood chip), pitch-based and synthetic resin-based. Among them, coal-based and wood-based activated carbon dominate the market due to their easy raw material availability, stable performance and controllable cost.

Technology Empowered, Scenario-Adapted Grinding Solutions

SBM has an in-depth insight into the raw material characteristics and process requirements of different types of activated carbon, optimizes the grinding process and equipment configuration in a targeted manner, and creates a full-process solution that can be rapidly implemented and covers all production scenarios. Through precise process design, rational equipment selection and an intelligent control system, it fully achieves the efficient, stable and green production of activated carbon powder.

Preparation Process of Coal-Based Activated Carbon

The preparation process of coal-based activated carbon includes raw material pretreatment, batching, carbonization, activation, post-treatment and optional modification treatment.

With scenario adaptation, cost reduction & efficiency improvement, and green compliance as its core principles, SBM relies on two core grinding machine series — LM and MTW, and leverages nearly 40 years of global project experience to deeply cultivate application scenarios in the activated carbon industry. Through customized solutions for the LM and MTW series grinding machines, it provides stable and reliable grinding equipment support for the industry.

Product Advantages

Integrates crushing, milling, drying, powder classification and conveying into a single unit.

Adopts a special roller and grinding disc structure design; the grinding rollers are equipped with a hydraulic automatic pressure device, featuring a larger grinding area and high milling efficiency.

Equipped with an automatic control system, enabling simple and flexible operation and reducing operation and maintenance costs.

Operates under full sealing and negative pressure conditions, with no dust overflow.

Product Advantages

Curved blade design expands the material grinding contact area and boosts milling efficiency.

Integrated bevel gear drive and resistance-free air inlet volute design ensure better material fluidity and lower energy consumption.

Low resistance leads to low oil temperature, with an oil change interval of up to 4 months and reduced maintenance frequency.

Globally Verified, Winning Customers' Trust with Tailored Solutions.

The equipment of SBM is exported to more than 180 countries and regions worldwide. In the activated carbon sector, our solutions have been applied across multiple sub-scenarios, all achieving the core goals of superior quality compliance, enhanced operational efficiency and environmental regulatory conformity. The stable performance of our equipment and the efficiency of our service response have earned high recognition from customers.