Deeply Engaged in Rare Earth Recycling: SBM Solves the Challenge of High-Value Utilization of NdFeB Scrap

As a core benchmark of the third-generation rare earth permanent magnet materials, NdFeB has become a pivotal functional material empowering the new energy revolution and the upgrading of intelligent manufacturing by virtue of its ultra-high magnetic energy product, outstanding coercivity and excellent energy density, and it strongly underpins the development of strategic emerging industries.

With the rapid iteration of industries such as new energy vehicles, wind power equipment and intelligent terminals, the market demand for high-performance rare earth permanent magnet materials has been surging continuously, opening up broader development space for the sector. Nevertheless, various types of scrap are inevitably generated throughout the entire life cycle of NdFeB permanent magnet materials, from production and processing to end-use applications. Such scrap mainly comes from two scenarios: first, the leftover bits, cutting dust and defective products produced in the manufacturing process; second, the retired waste products that have reached their service life. The rare earth resources contained in such scrap hold great recycling value.

At present, the mainstream technologies in the field of NdFeB scrap recycling fall into three major categories, each with distinctive features and advancing in synergy:

1. Pyrometallurgical processes: The core lies in separating rare earth elements through high-temperature treatment. Typical technologies include selective chlorination, liquid alloy process and slag-metal smelting separation, all boasting a high level of technological maturity.

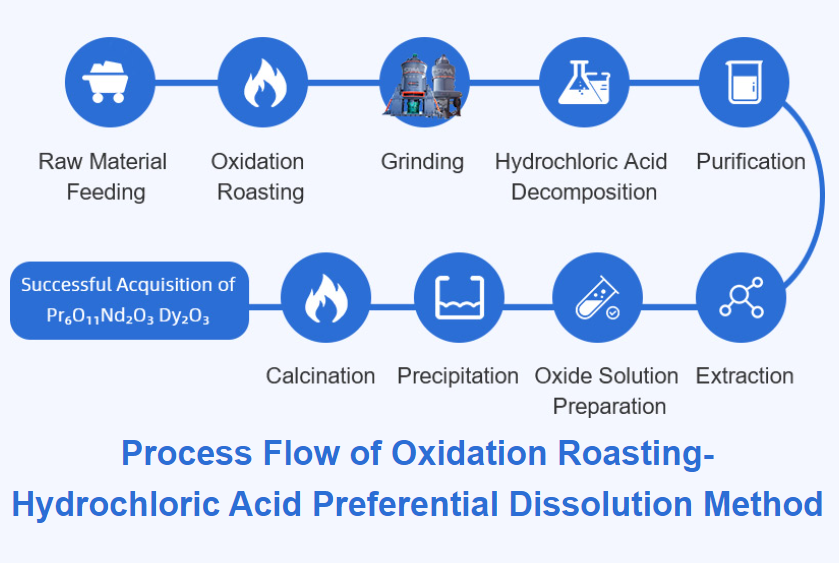

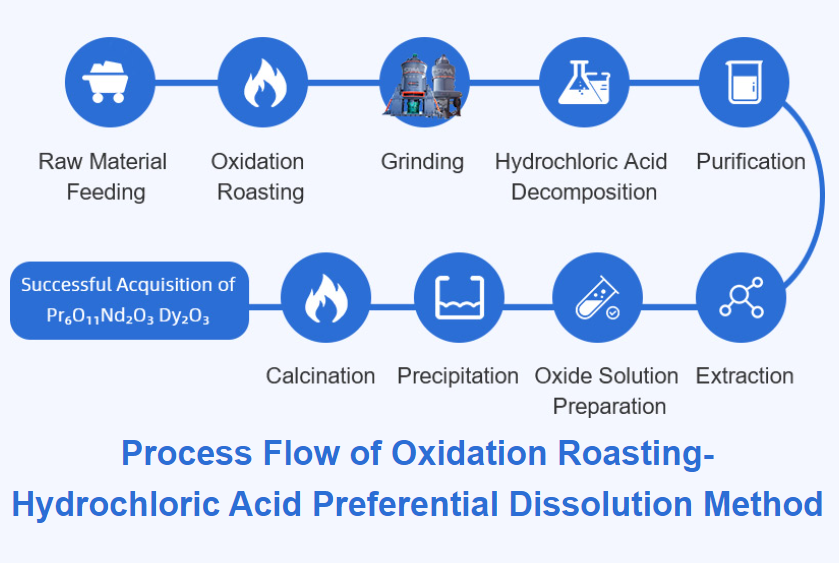

2. Hydrometallurgical processes: Centered on chemical leaching and separation, the mainstream technologies cover oxidative roasting-hydrchloric acid preferential leaching, total leaching and double salt precipitation, which demonstrate prominent advantages in resource recovery efficiency.

3. Emerging processes: Newly developed technologies such as hydrogen decrepitation, biohydrometallurgy, calcium thermal reduction and electrochemical leaching are achieving rapid breakthroughs. With their green and high-efficiency characteristics, these processes are gradually emerging as key R&D focuses in the industry.

Addressing the industry pain points of uneven material hardness after oxidative roasting and stringent requirements for precise particle size control, as well as the rigorous raw material quality standards across the entire recycling process, SBM leverages its nearly 40 years of in-depth expertise and technological accumulation in the grinding equipment sector to accurately capture the core industrial demands. We have tailor-made a dedicated grinding solution integrating professionalism, high efficiency and environmental friendliness for the NdFeB scrap recycling industry, injecting core impetus into the high-value cyclic utilization of rare earth resources.

SBM proudly launches two flagship core equipment: the LM Vertical Grinding Mill and the MTW European Trapezium Grinding Mill. Boasting high-efficiency grinding performance and precise particle size control capability, the equipment delivers high-quality raw materials for the impurity removal and extraction processes subsequent to rare earth leaching, effectively improving the recovery rate of rare earth resources. Equipped with intelligent energy-saving technologies and integrated with a full-process environmental protection design, the equipment drastically reduces production energy consumption and pollutant emissions, enabling the entire rare earth recycling process to meet green production standards.

Every SBM grinding mill stands as a solid cornerstone for building a sound green circular economy; every ton of rare earth resources efficiently recovered fuels the safeguarding of national resource security and the advancement of low-carbon development with robust impetus.

Going forward, SBM will continue to deepen its expertise in core grinding technologies, drive the upgrading of resource recycling through innovative R&D, and fully empower China’s rare earth industry to embark on a new journey of high-quality development. We will contribute Chinese strength to the global green and low-carbon transition with our exclusive SBM solutions.

With the rapid iteration of industries such as new energy vehicles, wind power equipment and intelligent terminals, the market demand for high-performance rare earth permanent magnet materials has been surging continuously, opening up broader development space for the sector. Nevertheless, various types of scrap are inevitably generated throughout the entire life cycle of NdFeB permanent magnet materials, from production and processing to end-use applications. Such scrap mainly comes from two scenarios: first, the leftover bits, cutting dust and defective products produced in the manufacturing process; second, the retired waste products that have reached their service life. The rare earth resources contained in such scrap hold great recycling value.

At present, the mainstream technologies in the field of NdFeB scrap recycling fall into three major categories, each with distinctive features and advancing in synergy:

1. Pyrometallurgical processes: The core lies in separating rare earth elements through high-temperature treatment. Typical technologies include selective chlorination, liquid alloy process and slag-metal smelting separation, all boasting a high level of technological maturity.

2. Hydrometallurgical processes: Centered on chemical leaching and separation, the mainstream technologies cover oxidative roasting-hydrchloric acid preferential leaching, total leaching and double salt precipitation, which demonstrate prominent advantages in resource recovery efficiency.

3. Emerging processes: Newly developed technologies such as hydrogen decrepitation, biohydrometallurgy, calcium thermal reduction and electrochemical leaching are achieving rapid breakthroughs. With their green and high-efficiency characteristics, these processes are gradually emerging as key R&D focuses in the industry.

Addressing the industry pain points of uneven material hardness after oxidative roasting and stringent requirements for precise particle size control, as well as the rigorous raw material quality standards across the entire recycling process, SBM leverages its nearly 40 years of in-depth expertise and technological accumulation in the grinding equipment sector to accurately capture the core industrial demands. We have tailor-made a dedicated grinding solution integrating professionalism, high efficiency and environmental friendliness for the NdFeB scrap recycling industry, injecting core impetus into the high-value cyclic utilization of rare earth resources.

SBM proudly launches two flagship core equipment: the LM Vertical Grinding Mill and the MTW European Trapezium Grinding Mill. Boasting high-efficiency grinding performance and precise particle size control capability, the equipment delivers high-quality raw materials for the impurity removal and extraction processes subsequent to rare earth leaching, effectively improving the recovery rate of rare earth resources. Equipped with intelligent energy-saving technologies and integrated with a full-process environmental protection design, the equipment drastically reduces production energy consumption and pollutant emissions, enabling the entire rare earth recycling process to meet green production standards.

Every SBM grinding mill stands as a solid cornerstone for building a sound green circular economy; every ton of rare earth resources efficiently recovered fuels the safeguarding of national resource security and the advancement of low-carbon development with robust impetus.

Going forward, SBM will continue to deepen its expertise in core grinding technologies, drive the upgrading of resource recycling through innovative R&D, and fully empower China’s rare earth industry to embark on a new journey of high-quality development. We will contribute Chinese strength to the global green and low-carbon transition with our exclusive SBM solutions.