SBM Powers Full Mechanical Completion of China’s Largest Coal-based Eco-friendly Carbon Materials Project

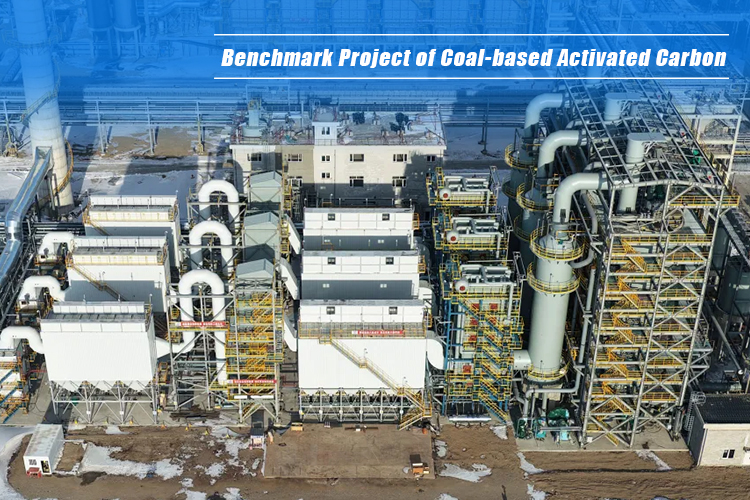

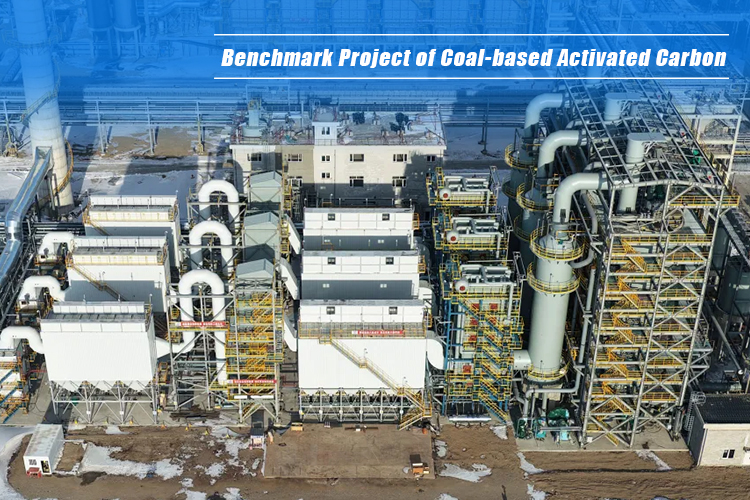

Good News Keeps Coming, and Great Achievements Keep Piling Up! Recently, the 150,000 t/a Coal-based Eco-friendly Carbon Materials Project of China Coal Huali has successfully achieved full mechanical completion, officially entering the preparation stage for joint commissioning.

As the supplier of the core grinding system for this project, SBM has precisely positioned two sets of its LM Vertical Coal Mills. The equipment is scheduled to fully enter joint commissioning in March 2026, which will mark the official launch of the project's trial production phase. This will hit the "acceleration button" for the high-quality commissioning of China's largest-scale and most highly automated coal-based activated carbon production base.

From "Fuel" to "Material": Building a New Benchmark for the Coal-based Activated Carbon Industry

As a benchmark project for industrial development in Xinjiang jointly undertaken by local and central enterprises, the China Coal Huali Project boasts a total investment of 3.334 billion yuan. Leveraging the low-ash, high-quality coal resources of the Jilangde Open-pit Coal Mine, it is committed to achieving clean conversion and high-efficiency utilization of coal resources. Upon reaching full production capacity, the project will process 680,000 tons of raw coal annually to produce 150,000 tons of high-performance coal-based eco-friendly carbon materials. These products will be widely applied in key environmental protection scenarios such as drinking water purification, industrial wastewater treatment, and VOCs abatement, while the project itself will serve as a national strategic reserve base for environmental emergency materials.

The project has successfully paved the way for the localization of coal-based hard carbon anode materials, breaking the long-standing bottleneck of over-reliance on imports for core materials of sodium-ion batteries and achieving a technological breakthrough in kiloton-scale mass production. This marks a substantial step forward in the coal industry's strategic transformation from "fuel" to "material"—and behind this industrial leap lies the robust empowerment of advanced grinding equipment and full-process services provided by SBM.

SBM Full-cycle Technical Support Lays a Solid Foundation for the High-quality Carbon Materials Industry

To meet the project's core standards of high automation, high environmental-friendliness and high safety, SBM focused on the key pain points in coal-based activated carbon production. Leveraging its proven EPC general contracting capabilities and strength in core equipment, SBM acted as a powerful driving engine for the efficient advancement of the project.

Coal Quality Adaptation and Optimization: Laying a Solid Foundation for the Production Process

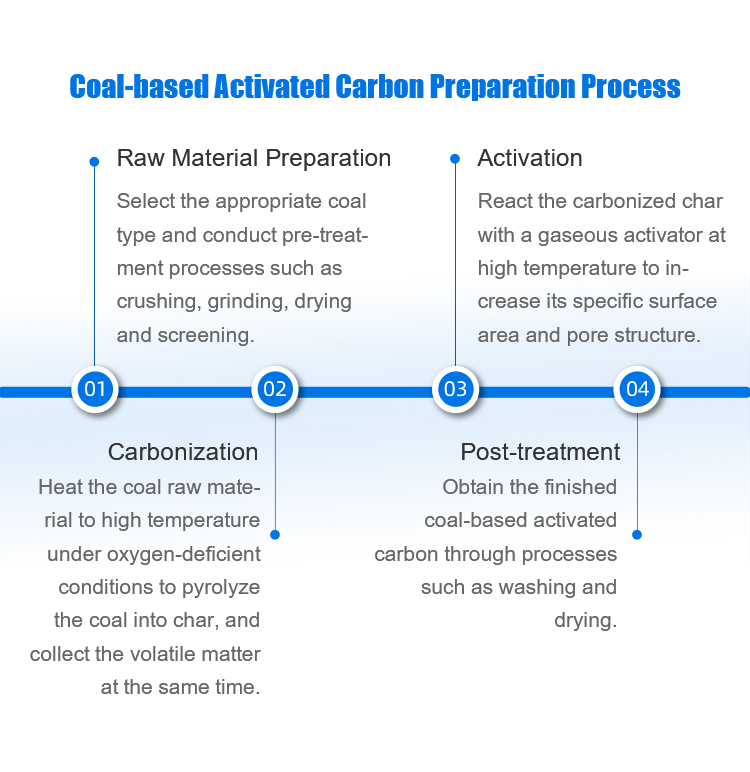

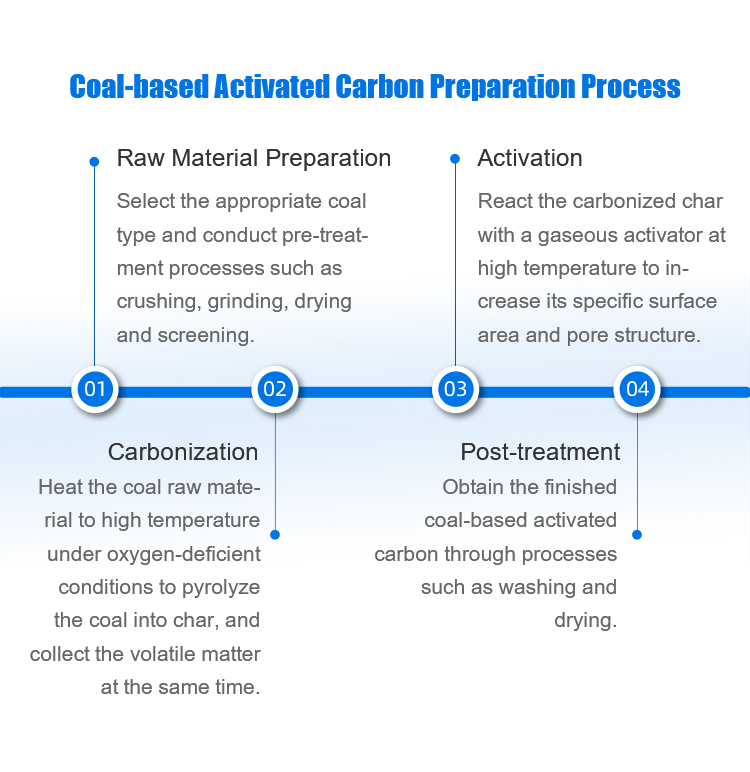

The preparation process of coal-based activated carbon consists of raw coal crushing → grinding → carbonization → activation → post-treatment. Grinding serves as a critical step: it refines the particle size of coal powder, increases its specific surface area, and significantly enhances the efficiency of subsequent activation reactions.

Drawing on years of experience in coal-based material processing, the technical team of SBM has carried out targeted optimization on the roller and disc structure of the LM Vertical Coal Mill. This enables precise control over the particle size distribution of the finished product, ensuring that the output material meets the stringent fineness requirements of subsequent processes such as carbonization and activation, thus providing a foundational guarantee for improving the adsorption performance of activated carbon.

Full-process Safety Prevention and Control for High-risk Operating Conditions

The coal grinding process is exposed to safety risks such as dust explosion. To address this, SBM has equipped its LM Vertical Coal Mill with a full-process safety explosion-proof system. Multiple protective measures are implemented to achieve full-coverage fire and explosion prevention across all zones and sources. Meanwhile, the equipment's sealing structure has been optimized to ensure stable operation under negative pressure conditions. This eliminates potential production safety hazards at the equipment level, fully meeting the project's stringent high-safety standards.

Precision On-site Deployment for Complex Scenarios

The project site imposed stringent requirements on construction conditions and equipment layout. SBM dispatched a professional installation team to work on-site, optimizing the equipment placement plan based on the characteristics of the on-site space to achieve a compact and rational layout.

Meanwhile, the team collaborated efficiently with construction teams responsible for civil engineering, electrical engineering and other processes, overcoming on-site operation challenges, ensuring the progress and quality of equipment installation, and reserving sufficient space for subsequent joint commissioning.

Intelligent System Integration to Meet Automation Requirements

To meet the project's requirements for large-scale and intelligent production, SBM has equipped its LM Vertical Mill with an intelligent central control system. This system enables real-time monitoring of equipment operating status, dynamic parameter adjustment and fault early warning, and can be seamlessly integrated into the project's overall automated management and control system, ensuring efficient and stable operation of the production process.

China National Coal Group's kiloton-scale coal-based hard carbon mass production project is not only a milestone in technological innovation, but also a model for the transformation and upgrading of the coal industry. Its successful experience will accelerate the application expansion of coal-based new materials in energy storage, environmental protection, high-end manufacturing and other fields, providing a replicable "China Coal Solution" for the transformation of traditional coal enterprises.

Focus on Green Transition to Promote the Upgrading of Coal-based Materials Industry

With nearly 40 years of deep cultivation in the powder processing sector, SBM has always adhered to the philosophy that "our success lies in our customers' success". Ranging from the supply of complete powder grinding production lines to EPC general contracting services, SBM focuses on its products and services, and takes green and intelligent integrated solutions as the core. We provide customized services for customers, enabling them to "one-stop" meet all their needs simply by cooperating with SBM.

SBM has now formed mature applications in the activated carbon field. We continue to provide customized solutions for various activated carbon manufacturers, covering all scenarios from large-scale mass production to small and medium-sized production lines. The scientificity of its equipment configuration and the effectiveness of solution implementation have won high recognition and extensive praise from customers.

As the supplier of the core grinding system for this project, SBM has precisely positioned two sets of its LM Vertical Coal Mills. The equipment is scheduled to fully enter joint commissioning in March 2026, which will mark the official launch of the project's trial production phase. This will hit the "acceleration button" for the high-quality commissioning of China's largest-scale and most highly automated coal-based activated carbon production base.

From "Fuel" to "Material": Building a New Benchmark for the Coal-based Activated Carbon Industry

As a benchmark project for industrial development in Xinjiang jointly undertaken by local and central enterprises, the China Coal Huali Project boasts a total investment of 3.334 billion yuan. Leveraging the low-ash, high-quality coal resources of the Jilangde Open-pit Coal Mine, it is committed to achieving clean conversion and high-efficiency utilization of coal resources. Upon reaching full production capacity, the project will process 680,000 tons of raw coal annually to produce 150,000 tons of high-performance coal-based eco-friendly carbon materials. These products will be widely applied in key environmental protection scenarios such as drinking water purification, industrial wastewater treatment, and VOCs abatement, while the project itself will serve as a national strategic reserve base for environmental emergency materials.

The project has successfully paved the way for the localization of coal-based hard carbon anode materials, breaking the long-standing bottleneck of over-reliance on imports for core materials of sodium-ion batteries and achieving a technological breakthrough in kiloton-scale mass production. This marks a substantial step forward in the coal industry's strategic transformation from "fuel" to "material"—and behind this industrial leap lies the robust empowerment of advanced grinding equipment and full-process services provided by SBM.

SBM Full-cycle Technical Support Lays a Solid Foundation for the High-quality Carbon Materials Industry

To meet the project's core standards of high automation, high environmental-friendliness and high safety, SBM focused on the key pain points in coal-based activated carbon production. Leveraging its proven EPC general contracting capabilities and strength in core equipment, SBM acted as a powerful driving engine for the efficient advancement of the project.

Coal Quality Adaptation and Optimization: Laying a Solid Foundation for the Production Process

The preparation process of coal-based activated carbon consists of raw coal crushing → grinding → carbonization → activation → post-treatment. Grinding serves as a critical step: it refines the particle size of coal powder, increases its specific surface area, and significantly enhances the efficiency of subsequent activation reactions.

Drawing on years of experience in coal-based material processing, the technical team of SBM has carried out targeted optimization on the roller and disc structure of the LM Vertical Coal Mill. This enables precise control over the particle size distribution of the finished product, ensuring that the output material meets the stringent fineness requirements of subsequent processes such as carbonization and activation, thus providing a foundational guarantee for improving the adsorption performance of activated carbon.

Full-process Safety Prevention and Control for High-risk Operating Conditions

The coal grinding process is exposed to safety risks such as dust explosion. To address this, SBM has equipped its LM Vertical Coal Mill with a full-process safety explosion-proof system. Multiple protective measures are implemented to achieve full-coverage fire and explosion prevention across all zones and sources. Meanwhile, the equipment's sealing structure has been optimized to ensure stable operation under negative pressure conditions. This eliminates potential production safety hazards at the equipment level, fully meeting the project's stringent high-safety standards.

Precision On-site Deployment for Complex Scenarios

The project site imposed stringent requirements on construction conditions and equipment layout. SBM dispatched a professional installation team to work on-site, optimizing the equipment placement plan based on the characteristics of the on-site space to achieve a compact and rational layout.

Meanwhile, the team collaborated efficiently with construction teams responsible for civil engineering, electrical engineering and other processes, overcoming on-site operation challenges, ensuring the progress and quality of equipment installation, and reserving sufficient space for subsequent joint commissioning.

Intelligent System Integration to Meet Automation Requirements

To meet the project's requirements for large-scale and intelligent production, SBM has equipped its LM Vertical Mill with an intelligent central control system. This system enables real-time monitoring of equipment operating status, dynamic parameter adjustment and fault early warning, and can be seamlessly integrated into the project's overall automated management and control system, ensuring efficient and stable operation of the production process.

China National Coal Group's kiloton-scale coal-based hard carbon mass production project is not only a milestone in technological innovation, but also a model for the transformation and upgrading of the coal industry. Its successful experience will accelerate the application expansion of coal-based new materials in energy storage, environmental protection, high-end manufacturing and other fields, providing a replicable "China Coal Solution" for the transformation of traditional coal enterprises.

Focus on Green Transition to Promote the Upgrading of Coal-based Materials Industry

With nearly 40 years of deep cultivation in the powder processing sector, SBM has always adhered to the philosophy that "our success lies in our customers' success". Ranging from the supply of complete powder grinding production lines to EPC general contracting services, SBM focuses on its products and services, and takes green and intelligent integrated solutions as the core. We provide customized services for customers, enabling them to "one-stop" meet all their needs simply by cooperating with SBM.

SBM has now formed mature applications in the activated carbon field. We continue to provide customized solutions for various activated carbon manufacturers, covering all scenarios from large-scale mass production to small and medium-sized production lines. The scientificity of its equipment configuration and the effectiveness of solution implementation have won high recognition and extensive praise from customers.