Continuity of Trust: SBM MTW Trapezium Mill Fully Ensures the Efficient Operation of Yunnan Prebaked Anode Project

As a fundamental segment supporting strategic industries such as aluminum and steel manufacturing, the carbon industry is embracing dual opportunities of scale expansion and structural upgrading. According to the latest data released by the China Carbon Industry Association, the total output of carbon products in China reached 7.5163 million tons in 2024, marking the industry's transition from scale-focused expansion to a green-oriented upgrade driven by quality and efficiency.

As one of the carbon products with the highest proportion, prebaked anodes are witnessing synchronous growth in market scale and technological advancement, and are rapidly evolving toward the direction of high performance, low consumption and long service life. Against this backdrop, a prebaked anode project with an annual output of 300,000 tons has been launched in Yunnan. The client is a long-term partner of SBM. Driven by trust, it has placed a repeat order. From contract signing to commissioning, the project only took 8 months. With its customized high-end powder grinding solutions, SBM has become a solid cornerstone supporting the efficient implementation of the project.

As a seasoned enterprise in China’s carbon industry, the client’s launch of the new prebaked anode project in Yunnan is not only a strategic move for its own expansion, but also an important piece in optimizing the regional aluminum industry ecosystem and strengthening the independent controllability of the supply chain.

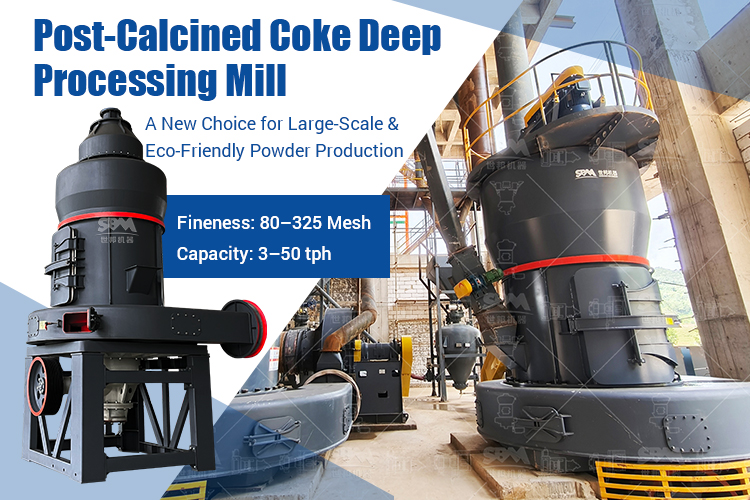

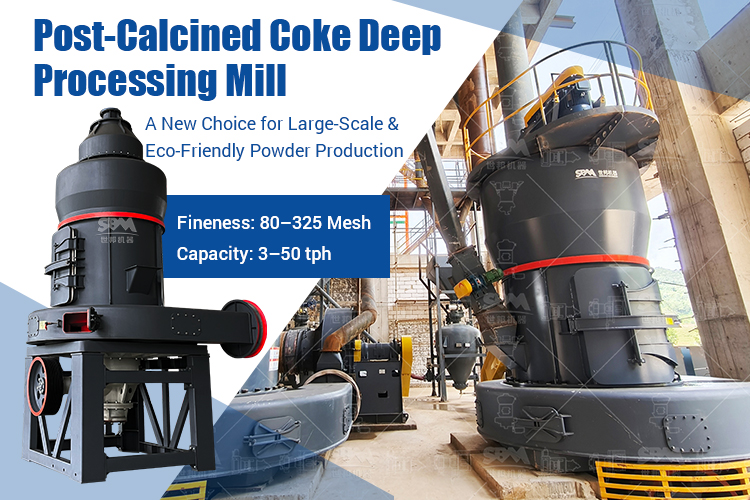

Material: Calcined Coke

Fineness: 200 Mesh

Application: Carbon Industry

Equipment: MTW European Trapezium Mill

From the consistent and reliable deliveries in the past to the smooth full-process implementation of this project, the tacit understanding accumulated through long-term collaboration has eliminated the need for repeated adjustments between the two parties. From customized solution design, equipment selection to on-site installation and commissioning, the professional control and wholehearted dedication in every link have verified the underlying logic of "value alignment" — precisely because both parties have a deep understanding of each other’s core demands, the cooperation can be promoted efficiently and implemented steadily.

The improvement in efficiency stems not only from reliable quality and rapid response, but also from the profound technical expertise and a large number of mature cases that SBM has accumulated over the years in the field of carbon raw material processing such as petroleum coke and calcined coke.

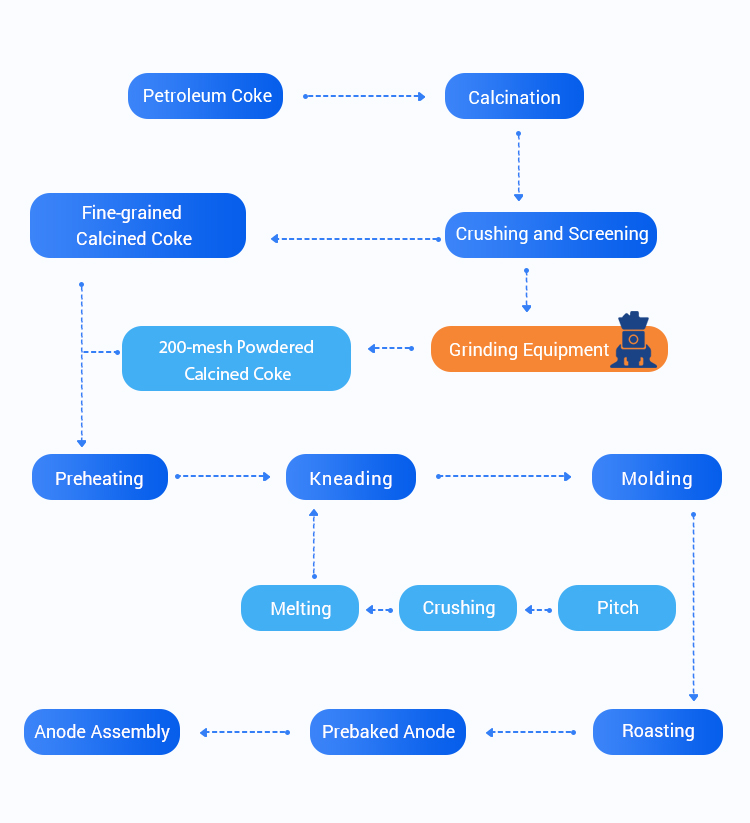

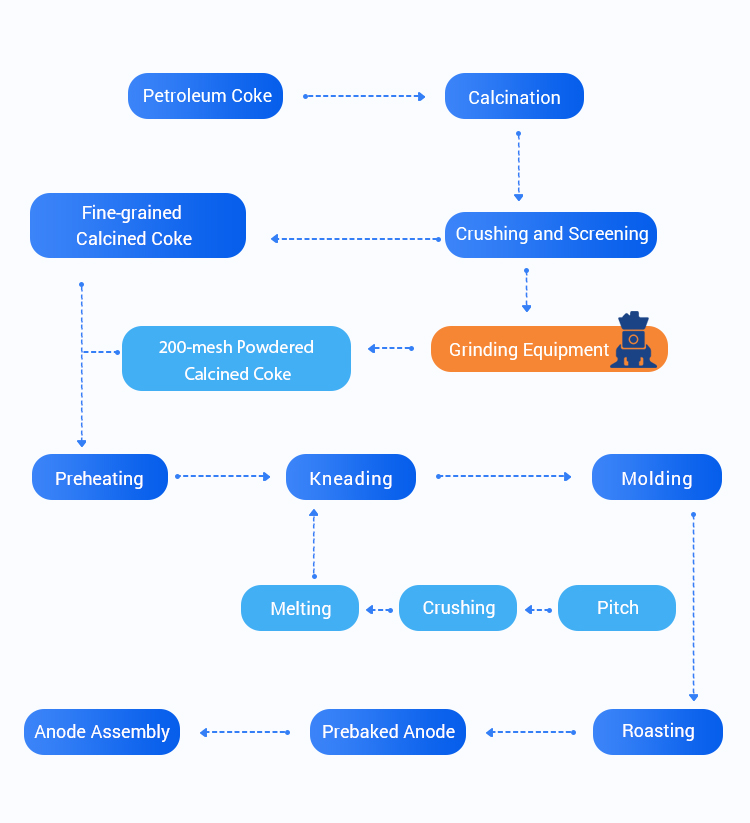

The production of prebaked anodes starts with the calcination of petroleum coke. Calcined coke must undergo a series of sophisticated processes including crushing, grinding, batching, kneading, forming and baking before it can be turned into qualified anode blocks. Among these processes, the grinding stage is recognized as a pivotal quality checkpoint that bridges the preceding and subsequent procedures.

Therefore, the client imposed exceptionally high standards on the equipment: it must ensure stable powder quality, efficient and energy-saving system operation, and large-scale production capacity to meet the annual output requirement of 300,000 tons. In addition, the equipment must feature high operational reliability to match the tight project commissioning schedule.

SBM has always focused on the technical pain points and development needs of the carbon industry, and built a comprehensive R&D, production and service system covering a full range of grinding equipment.

Faced with the client’s stringent requirements and project challenges, SBM provided a complete powder grinding system solution centered on four MTW European Trapezium Mill, and participated deeply in the project construction.

Aligning closely with the client's green development orientation and focusing on low energy consumption, environmental friendliness and industrial chain compatibility, SBM has further strengthened the equipment's eco-friendly performance and flexible adaptability on the basis of retaining MTW European Trapezium Mill inherent advantages of high efficiency and stability.

The four MTW European Trapezium Mills are arranged in a scientific layout, and an integrated optimization design has been implemented for the entire system covering feeding, grinding, collection and dust removal. This ensures smooth system operation and optimal energy consumption, delivering long-term economic benefits to the client.

The project required an ultra-short construction period of 8 months. Leveraging its robust production organization capabilities, mature modular pre-assembly experience and professional on-site service team, SBM ensured the on-time, high-quality delivery and installation of the equipment.

Technical service personnel were stationed on-site to provide collaborative support, quickly resolving issues during the commissioning process. This has greatly shortened the time from equipment installation to reaching the designed capacity and production standards, making a significant contribution to the project’s overall goal of "setting a new industry benchmark for speed".

As one of the carbon products with the highest proportion, prebaked anodes are witnessing synchronous growth in market scale and technological advancement, and are rapidly evolving toward the direction of high performance, low consumption and long service life. Against this backdrop, a prebaked anode project with an annual output of 300,000 tons has been launched in Yunnan. The client is a long-term partner of SBM. Driven by trust, it has placed a repeat order. From contract signing to commissioning, the project only took 8 months. With its customized high-end powder grinding solutions, SBM has become a solid cornerstone supporting the efficient implementation of the project.

As a seasoned enterprise in China’s carbon industry, the client’s launch of the new prebaked anode project in Yunnan is not only a strategic move for its own expansion, but also an important piece in optimizing the regional aluminum industry ecosystem and strengthening the independent controllability of the supply chain.

Material: Calcined Coke

Fineness: 200 Mesh

Application: Carbon Industry

Equipment: MTW European Trapezium Mill

From the consistent and reliable deliveries in the past to the smooth full-process implementation of this project, the tacit understanding accumulated through long-term collaboration has eliminated the need for repeated adjustments between the two parties. From customized solution design, equipment selection to on-site installation and commissioning, the professional control and wholehearted dedication in every link have verified the underlying logic of "value alignment" — precisely because both parties have a deep understanding of each other’s core demands, the cooperation can be promoted efficiently and implemented steadily.

The improvement in efficiency stems not only from reliable quality and rapid response, but also from the profound technical expertise and a large number of mature cases that SBM has accumulated over the years in the field of carbon raw material processing such as petroleum coke and calcined coke.

The production of prebaked anodes starts with the calcination of petroleum coke. Calcined coke must undergo a series of sophisticated processes including crushing, grinding, batching, kneading, forming and baking before it can be turned into qualified anode blocks. Among these processes, the grinding stage is recognized as a pivotal quality checkpoint that bridges the preceding and subsequent procedures.

Therefore, the client imposed exceptionally high standards on the equipment: it must ensure stable powder quality, efficient and energy-saving system operation, and large-scale production capacity to meet the annual output requirement of 300,000 tons. In addition, the equipment must feature high operational reliability to match the tight project commissioning schedule.

SBM has always focused on the technical pain points and development needs of the carbon industry, and built a comprehensive R&D, production and service system covering a full range of grinding equipment.

Faced with the client’s stringent requirements and project challenges, SBM provided a complete powder grinding system solution centered on four MTW European Trapezium Mill, and participated deeply in the project construction.

Aligning closely with the client's green development orientation and focusing on low energy consumption, environmental friendliness and industrial chain compatibility, SBM has further strengthened the equipment's eco-friendly performance and flexible adaptability on the basis of retaining MTW European Trapezium Mill inherent advantages of high efficiency and stability.

The four MTW European Trapezium Mills are arranged in a scientific layout, and an integrated optimization design has been implemented for the entire system covering feeding, grinding, collection and dust removal. This ensures smooth system operation and optimal energy consumption, delivering long-term economic benefits to the client.

The project required an ultra-short construction period of 8 months. Leveraging its robust production organization capabilities, mature modular pre-assembly experience and professional on-site service team, SBM ensured the on-time, high-quality delivery and installation of the equipment.

Technical service personnel were stationed on-site to provide collaborative support, quickly resolving issues during the commissioning process. This has greatly shortened the time from equipment installation to reaching the designed capacity and production standards, making a significant contribution to the project’s overall goal of "setting a new industry benchmark for speed".