Full Steam Ahead! SBM Powers the Full Commissioning of the 600,000 tons Prebaked Anode Project in Inner Mongolia

On the vast Inner Mongolia Plateau, a modern prebaked anode production base has risen rapidly. In October 2025, with the full commissioning of the 300,000-ton Phase II production line, this new 600,000 tons per year prebaked anode project achieved full-line operation. From the launch of Phase I to the full release of the 600,000 tons capacity of both phases, it took only a few months to complete the industry benchmark practice of "construction, commissioning and efficiency realization".

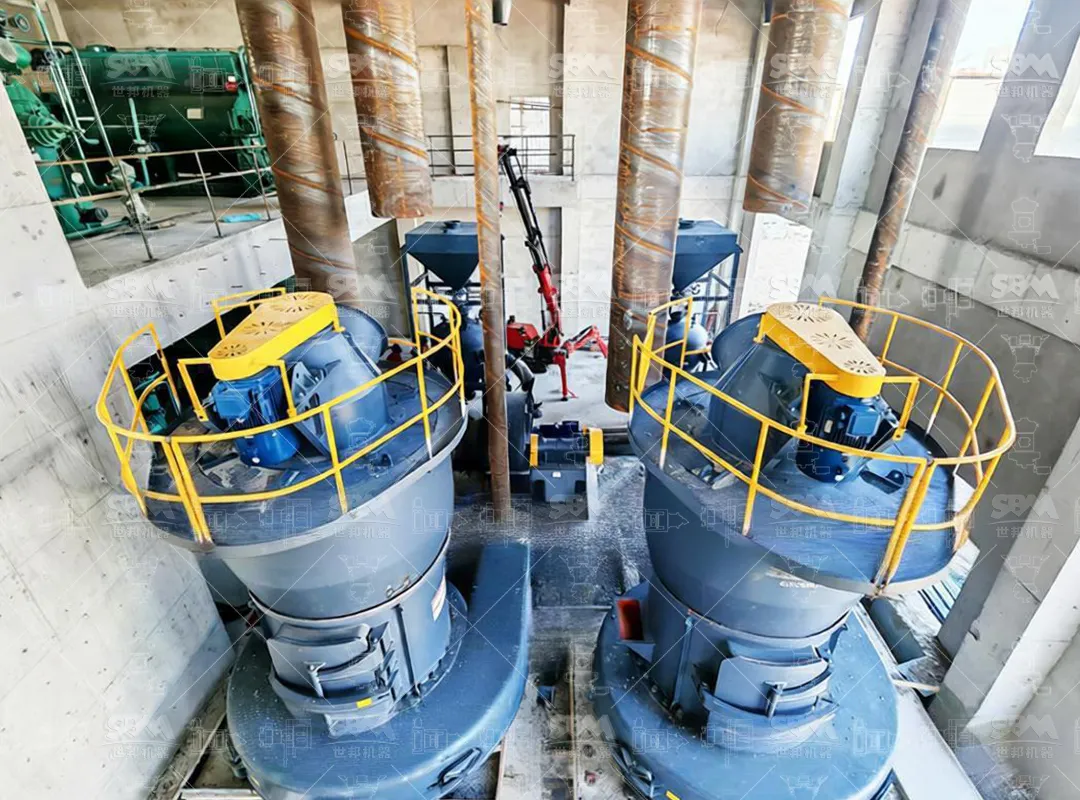

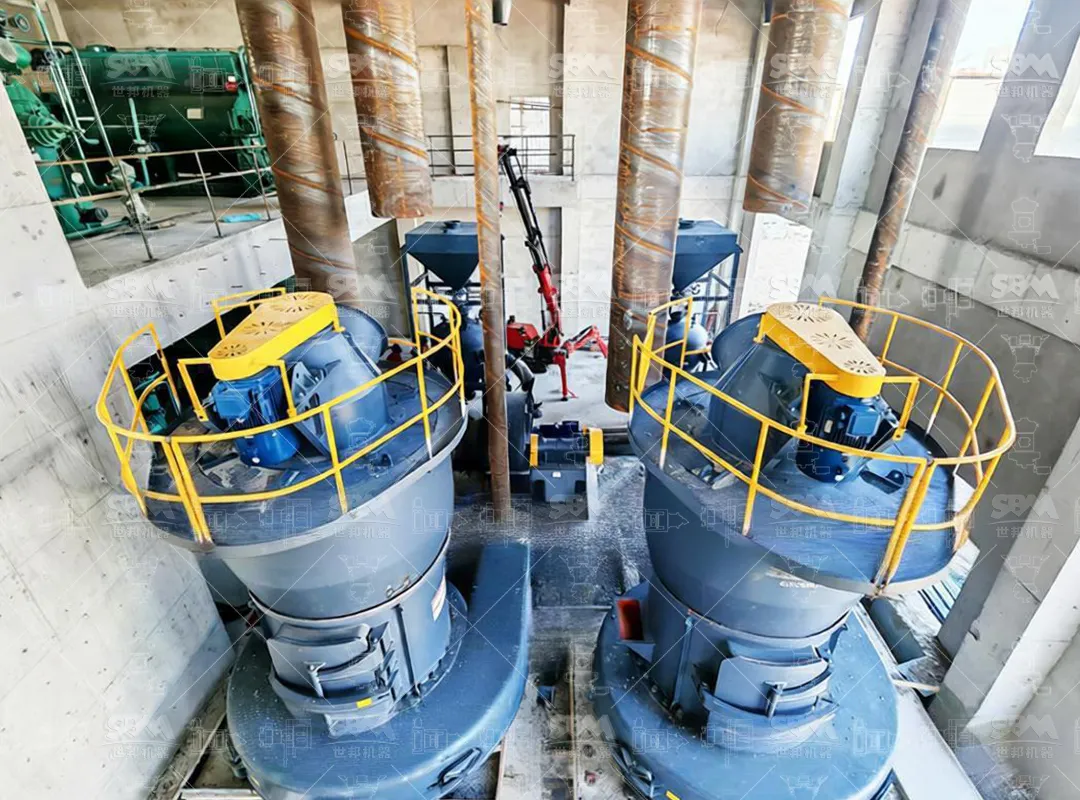

As the core grinding system supplier for this project, SBM provided equipment support with 8 units of MTW European Trapezium Mills, escorting the project from blueprint to reality throughout the entire process and helping the client build a domestically leading green carbon production base.

Thanks to its unique resource endowments and energy advantages, Inner Mongolia has emerged as a core hub for the domestic carbon industry layout. The successful commissioning of the client’s Phase II project marks a pivotal step for the client to expand its market footprint, and also represents a in-depth practice for SBM to leverage its equipment strength to empower the improvement and upgrading of the regional industrial chain, injecting robust impetus into the development of the local aluminum industry cluster.

Trust stems from strength, and cooperation is built on win-win outcomes. During the cooperation on the Phase I project, SBM conducted in-depth on-site operations, accurately adapted to the characteristics of local raw materials, climatic conditions and the client’s production requirements in Inner Mongolia. With stable and reliable equipment performance and full-life-cycle services, the company ensured the efficient implementation of the project, laying a solid foundation for the Phase II cooperation.

Highly recognizing SBM technological strength and service quality, the client once again selected SBM for the Phase II project, adding 4 more units of MTW European Version Trapezium Mill to continue the cooperation success story and set a new industry record for construction speed.

The quality of prebaked anodes is directly tied to the production efficiency and carbon emission levels of electrolytic aluminum. As a critical process, milling determines the precision and consistency of the final product. SBM MTW European Version Trapezium Mill accurately grind calcined coke to a uniform fineness of 200 mesh, providing stable and high-quality raw material support for high-end prebaked anodes, helping the client enhance product added value and seize a foothold in the high-end market.

"What impresses us most about the SBM team is their problem-solving capability and response speed. No matter what issues arise, they can always deliver professional solutions in a timely manner."

The smooth progress of the Phase II project has also earned high recognition from the client. From the management team to frontline operators, all have expressed their approval of the professional competence of the SBM team.

From the successful delivery of the Phase I project to the re-collaboration on Phase II, SBM services have spanned the entire life cycle of the project. Covering early-stage process planning and equipment selection, on-site installation and commissioning, operator training, as well as post-sales operation and maintenance support, the SBM service team has consistently ensured the rapid ramp-up to full capacity and stable operation of the production line through a professional, efficient and closed-loop service system.

From design blueprints to production lines, and from technological innovation to industrial upgrading, SBM empowers development through technology. In the future, we will join hands with industry partners to jointly drive the sustainable development of the prebaked anode industry and inject new impetus into the green transformation of the global electrolytic aluminum industry.

With nearly 40 years of dedicated experience in the milling sector, SBM has developed a full-chain solution spanning from raw material processing to finished product preparation. We have built a number of prebaked anode production lines for various large-scale carbon enterprises, covering projects of different scales with annual output ranging from 50,000 to 600,000 tons. Our technological maturity and market reputation have been consistently leading the industry.

As the core grinding system supplier for this project, SBM provided equipment support with 8 units of MTW European Trapezium Mills, escorting the project from blueprint to reality throughout the entire process and helping the client build a domestically leading green carbon production base.

Thanks to its unique resource endowments and energy advantages, Inner Mongolia has emerged as a core hub for the domestic carbon industry layout. The successful commissioning of the client’s Phase II project marks a pivotal step for the client to expand its market footprint, and also represents a in-depth practice for SBM to leverage its equipment strength to empower the improvement and upgrading of the regional industrial chain, injecting robust impetus into the development of the local aluminum industry cluster.

Trust stems from strength, and cooperation is built on win-win outcomes. During the cooperation on the Phase I project, SBM conducted in-depth on-site operations, accurately adapted to the characteristics of local raw materials, climatic conditions and the client’s production requirements in Inner Mongolia. With stable and reliable equipment performance and full-life-cycle services, the company ensured the efficient implementation of the project, laying a solid foundation for the Phase II cooperation.

Highly recognizing SBM technological strength and service quality, the client once again selected SBM for the Phase II project, adding 4 more units of MTW European Version Trapezium Mill to continue the cooperation success story and set a new industry record for construction speed.

The quality of prebaked anodes is directly tied to the production efficiency and carbon emission levels of electrolytic aluminum. As a critical process, milling determines the precision and consistency of the final product. SBM MTW European Version Trapezium Mill accurately grind calcined coke to a uniform fineness of 200 mesh, providing stable and high-quality raw material support for high-end prebaked anodes, helping the client enhance product added value and seize a foothold in the high-end market.

"What impresses us most about the SBM team is their problem-solving capability and response speed. No matter what issues arise, they can always deliver professional solutions in a timely manner."

The smooth progress of the Phase II project has also earned high recognition from the client. From the management team to frontline operators, all have expressed their approval of the professional competence of the SBM team.

From the successful delivery of the Phase I project to the re-collaboration on Phase II, SBM services have spanned the entire life cycle of the project. Covering early-stage process planning and equipment selection, on-site installation and commissioning, operator training, as well as post-sales operation and maintenance support, the SBM service team has consistently ensured the rapid ramp-up to full capacity and stable operation of the production line through a professional, efficient and closed-loop service system.

From design blueprints to production lines, and from technological innovation to industrial upgrading, SBM empowers development through technology. In the future, we will join hands with industry partners to jointly drive the sustainable development of the prebaked anode industry and inject new impetus into the green transformation of the global electrolytic aluminum industry.

With nearly 40 years of dedicated experience in the milling sector, SBM has developed a full-chain solution spanning from raw material processing to finished product preparation. We have built a number of prebaked anode production lines for various large-scale carbon enterprises, covering projects of different scales with annual output ranging from 50,000 to 600,000 tons. Our technological maturity and market reputation have been consistently leading the industry.