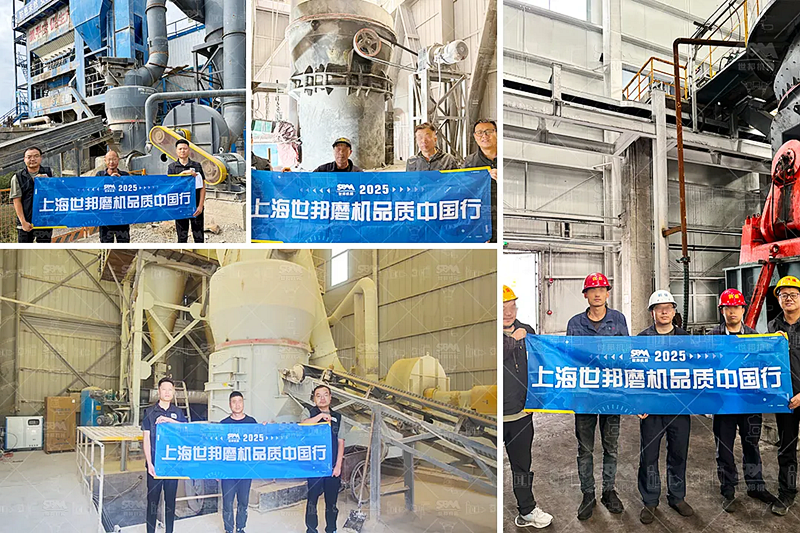

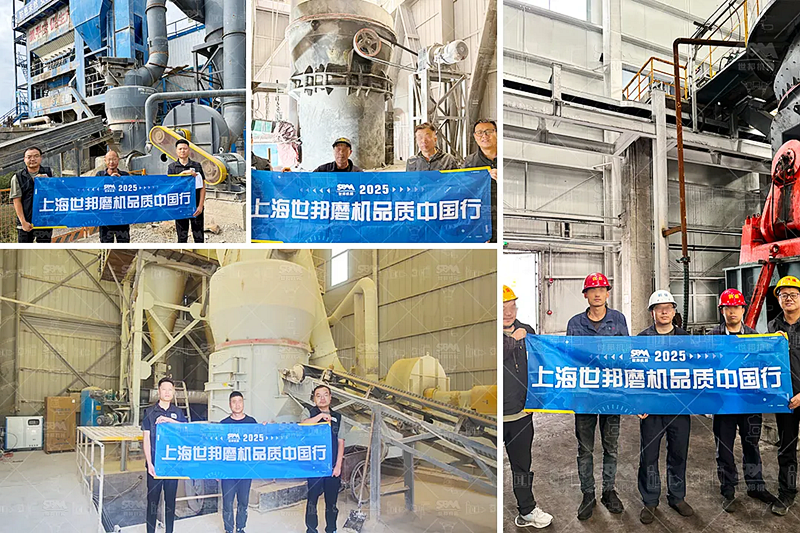

2025 SBM After-sales Service Tour of Grinding Mill - Shanxi Station

In the long course of industrial development, equipment quality that truly stands the test stems not only from precise calculations in laboratories but also from daily practical verification at production sites. 2025 SBM After-sales Service Tour of Grinding Mill has been ongoing for nine years, with professional technical teams traveling across the country to revisit numerous customer sites.

SBM revisit team arrived in the land of Sanjin (Shanxi), went deep into multiple key milling projects, conducted on-site visits and equipment inspections, listened to the most authentic voices of the market, and witnessed how SBM equipment helps customers improve efficiency and drive the transformation and upgrading of the industry.

Limestone Grinding Production Line

The project adopts SBM MTW European Trapezium Mill to produce 200 mesh limestone powder for the power plant's desulfurization system. The mill's advanced transmission system and high-precision classification technology ensure the limestone powder has uniform fineness and sufficient output.

The high reliability of SBM MTW European Trapezium Mill strongly supports the continuous and stable operation of the power plant's desulfurization system, helping the customer achieve environmental emission reduction goals while realizing economic benefits.

Material: Limestone

Fineness: 200 Mesh

Application: Power Plant Desulfurization

Equipment: MTW European Trapezium Mill

Spinel Grinding Production Line

SBM MTM Medium-Speed Trapezium Mill undertakes the task of processing high-hardness spinel into 200-mesh powder, which is used for manufacturing high-performance refractory materials.

To address the industry challenge of milling high-hardness materials, the mill adopts high-quality wear-resistant materials and a scientific curved surface design. This provides solid support for customers to produce high-quality refractory materials and successfully overcomes the industry difficulty in processing hard materials.

Material: Spinel

Fineness: 200 Mesh

Application: Refractory Materials

Equipment: MTM Medium-Speed Trapezium Mill

Limestone Grinding Production Line

The project uses SBM MTW European Trapezium Mill to grind limestone into 120 mesh powder. The finished product is stably supplied to surrounding cement and asphalt mixing plants, ensuring the quality and supply of basic materials for construction projects.

Against the backdrop of the building materials industry’s extremely high requirements for stability and supply guarantee, MTW European Trapezium Mill, with its efficient grinding and stable operation, ensures consistent finished product quality. It has become a reliable support for customers to maintain the stability of the downstream supply chain and enhance market competitiveness.

Material: Limestone

Fineness: 120 Mesh

Application: Cement and Asphalt Mixing Plants

Equipment: MTW European Trapezium Mill

Raw Coal Grinding Production Line

SBM LM Vertical Mill finely processes raw coal into 325-mesh powder, which is used for producing briquetted activated carbon. This has successfully promoted the transformation of coal resources into the high-end chemical industry field.

Facing the industry challenges of limited added value and high environmental pressure in traditional coal utilization methods, LM Vertical Mill, relying on its integrated design and high-efficiency milling technology, achieves stable operation with large output and low energy consumption. The finished product has uniform and reliable particle size, helping customers gain significant market competitive advantages and becoming a model for clean and efficient coal utilization.

Material: Raw Coal

Fineness: 325 Mesh

Application: Briquetted Activated Carbon

Equipment Used: LM Vertical Mill

Limestone Grinding Production Line

Large-scale power plants have large-scale desulfurization needs and strict requirements for the continuity of raw material supply. SBM MTW European Trapezium Mill enables batch processing and stable supply of raw materials, stably producing high-quality 250-mesh limestone powder. This effectively enhances the purification capacity of the desulfurization system, helping customers reduce the dosage of desulfurizing agents and lower environmental operation costs.

Material: Limestone

Fineness: 250 Mesh

Application: Power Plant Desulfurization

Equipment: MTW European Trapezium Mill

Short-term cooperation relies on products, while long-term win-win outcomes depend on services. During return visits to multiple projects in Shanxi, technicians not only solved equipment operation and maintenance issues but also taught on-site operators skills for daily monitoring and wear prevention, fundamentally improving equipment stability and service life.

SBM return visit team also listened to customer feedback and transformed service experience into data support for product iteration and upgrading, forming a positive cycle of "demand-driven R&D and service-optimized products". This full-process service concept has earned SBM wide recognition from customers in Shanxi.

SBM revisit team arrived in the land of Sanjin (Shanxi), went deep into multiple key milling projects, conducted on-site visits and equipment inspections, listened to the most authentic voices of the market, and witnessed how SBM equipment helps customers improve efficiency and drive the transformation and upgrading of the industry.

Limestone Grinding Production Line

The project adopts SBM MTW European Trapezium Mill to produce 200 mesh limestone powder for the power plant's desulfurization system. The mill's advanced transmission system and high-precision classification technology ensure the limestone powder has uniform fineness and sufficient output.

The high reliability of SBM MTW European Trapezium Mill strongly supports the continuous and stable operation of the power plant's desulfurization system, helping the customer achieve environmental emission reduction goals while realizing economic benefits.

Material: Limestone

Fineness: 200 Mesh

Application: Power Plant Desulfurization

Equipment: MTW European Trapezium Mill

Spinel Grinding Production Line

SBM MTM Medium-Speed Trapezium Mill undertakes the task of processing high-hardness spinel into 200-mesh powder, which is used for manufacturing high-performance refractory materials.

To address the industry challenge of milling high-hardness materials, the mill adopts high-quality wear-resistant materials and a scientific curved surface design. This provides solid support for customers to produce high-quality refractory materials and successfully overcomes the industry difficulty in processing hard materials.

Material: Spinel

Fineness: 200 Mesh

Application: Refractory Materials

Equipment: MTM Medium-Speed Trapezium Mill

Limestone Grinding Production Line

The project uses SBM MTW European Trapezium Mill to grind limestone into 120 mesh powder. The finished product is stably supplied to surrounding cement and asphalt mixing plants, ensuring the quality and supply of basic materials for construction projects.

Against the backdrop of the building materials industry’s extremely high requirements for stability and supply guarantee, MTW European Trapezium Mill, with its efficient grinding and stable operation, ensures consistent finished product quality. It has become a reliable support for customers to maintain the stability of the downstream supply chain and enhance market competitiveness.

Material: Limestone

Fineness: 120 Mesh

Application: Cement and Asphalt Mixing Plants

Equipment: MTW European Trapezium Mill

Raw Coal Grinding Production Line

SBM LM Vertical Mill finely processes raw coal into 325-mesh powder, which is used for producing briquetted activated carbon. This has successfully promoted the transformation of coal resources into the high-end chemical industry field.

Facing the industry challenges of limited added value and high environmental pressure in traditional coal utilization methods, LM Vertical Mill, relying on its integrated design and high-efficiency milling technology, achieves stable operation with large output and low energy consumption. The finished product has uniform and reliable particle size, helping customers gain significant market competitive advantages and becoming a model for clean and efficient coal utilization.

Material: Raw Coal

Fineness: 325 Mesh

Application: Briquetted Activated Carbon

Equipment Used: LM Vertical Mill

Limestone Grinding Production Line

Large-scale power plants have large-scale desulfurization needs and strict requirements for the continuity of raw material supply. SBM MTW European Trapezium Mill enables batch processing and stable supply of raw materials, stably producing high-quality 250-mesh limestone powder. This effectively enhances the purification capacity of the desulfurization system, helping customers reduce the dosage of desulfurizing agents and lower environmental operation costs.

Material: Limestone

Fineness: 250 Mesh

Application: Power Plant Desulfurization

Equipment: MTW European Trapezium Mill

Short-term cooperation relies on products, while long-term win-win outcomes depend on services. During return visits to multiple projects in Shanxi, technicians not only solved equipment operation and maintenance issues but also taught on-site operators skills for daily monitoring and wear prevention, fundamentally improving equipment stability and service life.

SBM return visit team also listened to customer feedback and transformed service experience into data support for product iteration and upgrading, forming a positive cycle of "demand-driven R&D and service-optimized products". This full-process service concept has earned SBM wide recognition from customers in Shanxi.