SBM LM Vertical Mill Empowers Yunnan's 40,0000 tons Prebaked Anode Project

Today, as the "dual carbon" strategy advances in depth, Yunnan, leveraging its unique hydropower resource advantages, is accelerating the construction of a green and low-carbon aluminum industry ecosystem.

With core technological breakthroughs and rich project experience, SBM has tailored an LM280M vertical grinding system for Yunnan's 400,000 ton/year prebaked anode project. This not only fills the domestic application gap of large-capacity single-unit milling equipment for calcined coke but also promotes the transformation and upgrading of the local aluminum industry through green intelligent manufacturing solutions.

Anchoring the Upgrade of Green Aluminum Industry

Leveraging its position as a key hub in the "West-to-East Power Transmission" program, Yunnan has formed an industrial cluster centered on green hydropower aluminum materials. The customer's planned 400,000 ton/year prebaked anode project serves as a core supporting project for the integrated green hydropower-aluminum material initiative.

Building on the local advantage of abundant hydropower resources, the project takes "forging a zero-carbon aluminum industry ecological closed loop" as its core goal, establishing a vertical green industrial chain system spanning from anode carbon preparation to electrolytic aluminum production.

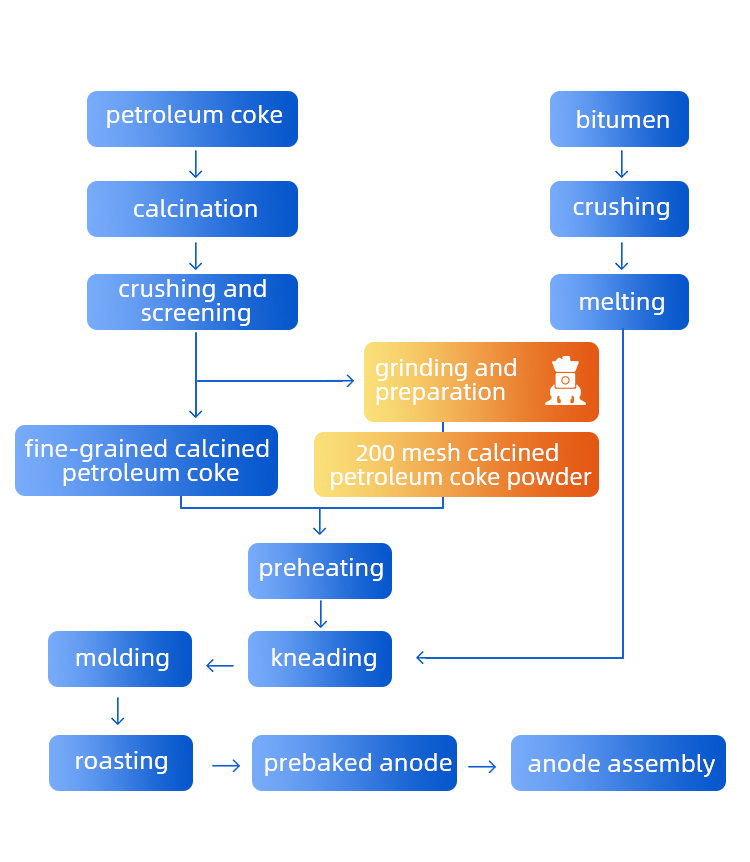

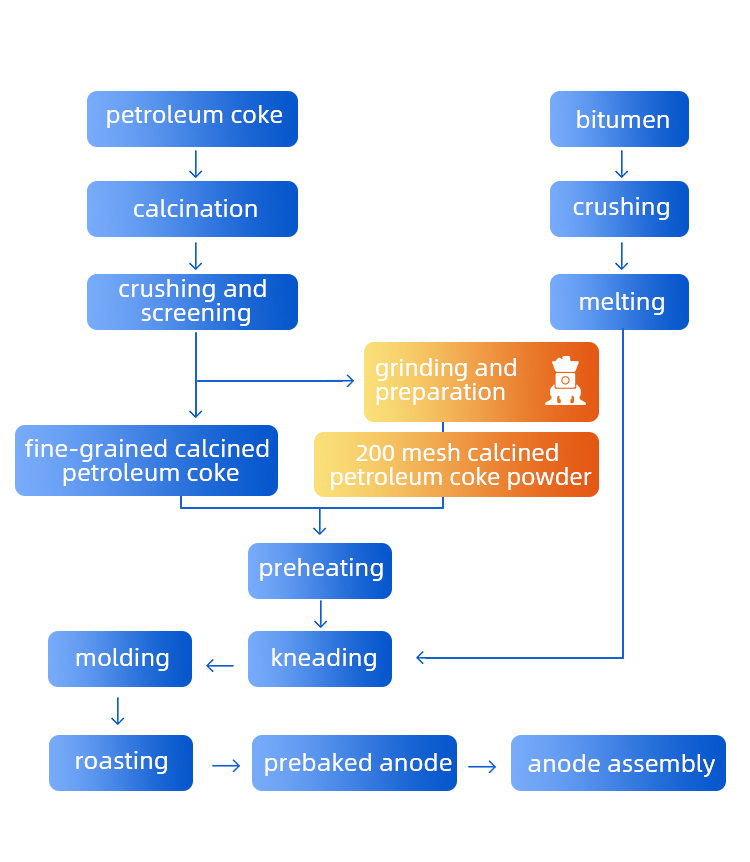

Processed Material: Calcined Coke

Finished Product Particle Size: 200 Mesh

Application Field: Prebaked Anode

Equipment Used: LM Vertical Mill

The customer clearly put forward the equipment selection criteria of "green, efficient and stable". With numerous successful cases in the petroleum coke field and customized design solutions, SBM ultimately won favor for its "lower whole-life-cycle cost and more efficient operation and maintenance response".

As the core supplier of the project, SBM provides a complete set of milling systems, covering the entire process from design, material selection, manufacturing to operation guarantee, installation guidance, test run, acceptance and training. The service scope starts from the pressure-resistant weighing coal feeder under the pre-milling silo and ends at the discharge port of the screw conveyor at the lower end of the pulse dust collector, realizing a "turnkey" delivery.

In response to the customer's needs, SBM set up a special technical team to tackle the three key process challenges proposed for the project: equipment configuration, environmental emission compliance, and finished product purity, achieving breakthroughs one by one:

Hardware configuration: Core components of the LM vertical mill, such as grinding rollers and bearings, are all selected from well-known international and domestic brands to ensure trouble-free continuous operation of the equipment.

Environmental compliance: Yunnan implements ultra-low standards for industrial waste gas emissions, requiring simultaneous treatment of dust-containing exhaust gas and volatile organic compounds (VOCs).

Purity control: An online particle size detector is configured to monitor the fineness of finished products in real time, ensuring stable fineness of finished products.

Currently, the equipment has been commissioned and operates stably for a long time. The equipment operation data and finished product parameters fully meet the planned expectations, and the customer highly appreciates the equipment performance and process adaptability. The LM vertical milling machine, with its stable performance and high-efficiency output, has become the "anchor" of the customer's production line.

Looking ahead, the carbon industry is undergoing profound changes. SBM will always adhere to the core philosophy of "craftsmanship in manufacturing, green development". Through the whole-life-cycle solution integrating "equipment + service + data", we will continue to provide green solutions of SBM Intelligent Manufacturing, contributing Chinese wisdom and strength to the sustainable development of the global carbon industry.

With core technological breakthroughs and rich project experience, SBM has tailored an LM280M vertical grinding system for Yunnan's 400,000 ton/year prebaked anode project. This not only fills the domestic application gap of large-capacity single-unit milling equipment for calcined coke but also promotes the transformation and upgrading of the local aluminum industry through green intelligent manufacturing solutions.

Anchoring the Upgrade of Green Aluminum Industry

Leveraging its position as a key hub in the "West-to-East Power Transmission" program, Yunnan has formed an industrial cluster centered on green hydropower aluminum materials. The customer's planned 400,000 ton/year prebaked anode project serves as a core supporting project for the integrated green hydropower-aluminum material initiative.

Building on the local advantage of abundant hydropower resources, the project takes "forging a zero-carbon aluminum industry ecological closed loop" as its core goal, establishing a vertical green industrial chain system spanning from anode carbon preparation to electrolytic aluminum production.

Processed Material: Calcined Coke

Finished Product Particle Size: 200 Mesh

Application Field: Prebaked Anode

Equipment Used: LM Vertical Mill

The customer clearly put forward the equipment selection criteria of "green, efficient and stable". With numerous successful cases in the petroleum coke field and customized design solutions, SBM ultimately won favor for its "lower whole-life-cycle cost and more efficient operation and maintenance response".

As the core supplier of the project, SBM provides a complete set of milling systems, covering the entire process from design, material selection, manufacturing to operation guarantee, installation guidance, test run, acceptance and training. The service scope starts from the pressure-resistant weighing coal feeder under the pre-milling silo and ends at the discharge port of the screw conveyor at the lower end of the pulse dust collector, realizing a "turnkey" delivery.

In response to the customer's needs, SBM set up a special technical team to tackle the three key process challenges proposed for the project: equipment configuration, environmental emission compliance, and finished product purity, achieving breakthroughs one by one:

Hardware configuration: Core components of the LM vertical mill, such as grinding rollers and bearings, are all selected from well-known international and domestic brands to ensure trouble-free continuous operation of the equipment.

Environmental compliance: Yunnan implements ultra-low standards for industrial waste gas emissions, requiring simultaneous treatment of dust-containing exhaust gas and volatile organic compounds (VOCs).

Purity control: An online particle size detector is configured to monitor the fineness of finished products in real time, ensuring stable fineness of finished products.

Currently, the equipment has been commissioned and operates stably for a long time. The equipment operation data and finished product parameters fully meet the planned expectations, and the customer highly appreciates the equipment performance and process adaptability. The LM vertical milling machine, with its stable performance and high-efficiency output, has become the "anchor" of the customer's production line.

Looking ahead, the carbon industry is undergoing profound changes. SBM will always adhere to the core philosophy of "craftsmanship in manufacturing, green development". Through the whole-life-cycle solution integrating "equipment + service + data", we will continue to provide green solutions of SBM Intelligent Manufacturing, contributing Chinese wisdom and strength to the sustainable development of the global carbon industry.