2025 SBM After-Sales Service Tour of Grinding Mill at Hebei Station

SBM powder grinding equipment, relying on its strong and excellent performance, has achieved in-depth application in multiple industries such as electric power, building materials, mining, and metallurgy. It accurately covers segmented fields including environmental protection desulfurization limestone powder preparation, large-scale non-metallic mineral powder making, heavy calcium processing, pulverized coal preparation, petroleum coke grinding, and ground granulated blast-furnace slag (GGBFS) production.

Currently, SBM powder grinding equipment has continuously served over 180 countries and regions worldwide. With its stable and efficient product performance and comprehensive after-sales service system, it has become the preferred high-end equipment solution for customers in the powder processing industry at home and abroad.

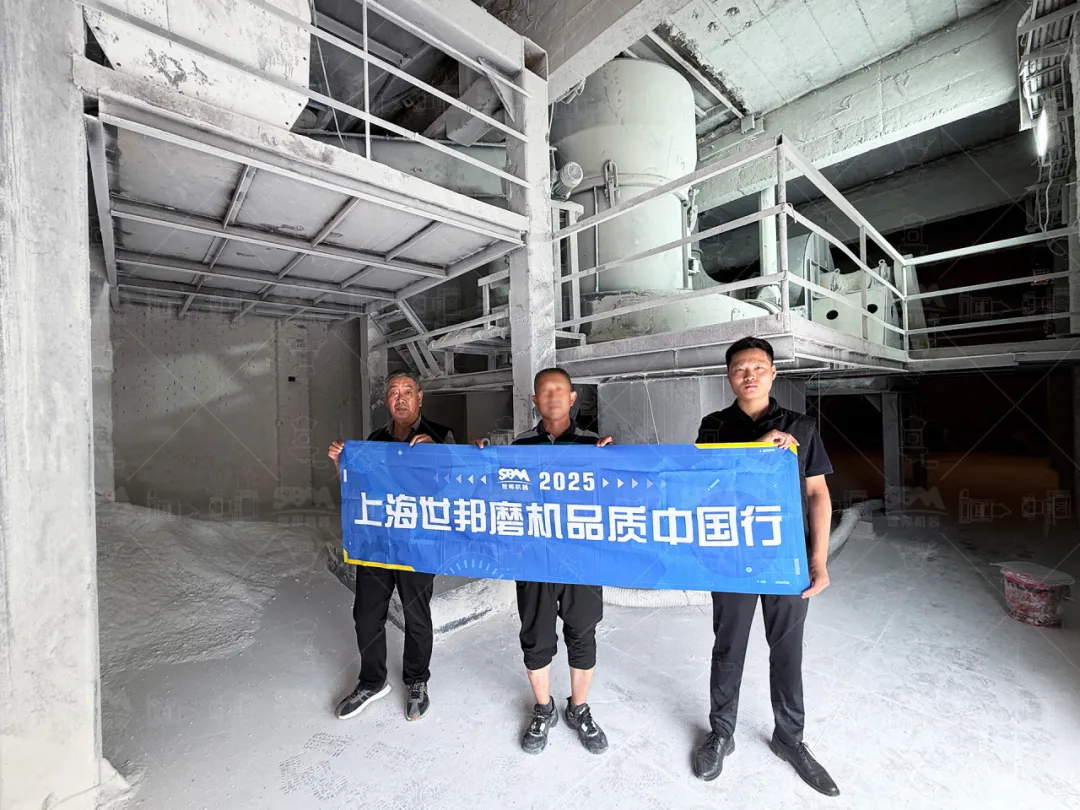

Recently, the return visit team of SBM After-Sales Service Tour of Grinding Mill arrived as scheduled, launching an in-depth service journey in Hebei and providing solid technical support and service guarantees for the development of local enterprises.

Eight years of continuous return visits have witnessed the leapfrog growth of customer enterprises. Many enterprises that partnered with SBM in the early years have developed from their initial start-up scale into backbone forces in the industry.

A power plant desulfurization enterprise in in-depth cooperation with SBM has three MTW European trapezium grinding mill purchased from SBM. After years of continuous operation, these machines still maintain strong performance, and the return visit inspection shows that the equipment is in excellent condition.

Processed Material: Limestone

Finished Product Fineness: 200 Mesh

Finished Product Application: Steel Plant Desulfurization

Equipment: MTW European trapezium grinding mill

The customer stated, "Choosing SBM means choosing stability and reliability. These devices are not only production tools, but also witnesses and participants in the development of our enterprise."

Processed Material: Calcined Coke

Finished Product Fineness: 200 Mesh

Finished Product Application: New Energy Anode Material

Equipment: MTW European trapezium grinding mill

Focused on quality, aligned in service. SBM engineers consider all aspects for customers: during the inspection, they found slight wear on the grinding rollers, which was within the expected range. Nevertheless, they still formulated a detailed preventive maintenance plan for the customer and trained the customer's employees on equipment maintenance and care measures to ensure the long-term stable operation of the equipment.

Thoughtful service has won unanimous praise from customers: "We are very satisfied with SBM's after-sales service. Any problems are solved in the first place, and it is clear from this annual return visit activity that SBM is a responsible and accountable major brand worthy of trust!"

Processed Material: Limestone

Equipment Used: MTW European trapezium grinding mill

SBM's service goal is to free customers from worries, and various actions are also practicing this concept. "From the punctuality of equipment delivery, to the professionalism of installation and commissioning, and then to the timeliness of after-sales maintenance, SBM has demonstrated strong capabilities in all links," the customer commented on the excellent cooperation results.

These high praises from customers are exactly the original aspiration of SBM's all-round service. With "full-cycle companionship" as the core of its service, SBM covers the entire life cycle of equipment from pre-sales, in-sales to after-sales. This goes beyond the simple attribute of SBM's equipment as a production tool, turning it into a partner that grows together with customers.

SBM After-Sales Service Tour of Grinding Mill is more than just a one-time return visit; it is committed to building a long-term cooperative ecosystem. The return visit team implements a standardized process to provide customers with comprehensive inspection, maintenance and repair services.

Everywhere they go, the engineer team conducts a comprehensive inspection of the equipment, including recording the original equipment operation data, checking the finished product fineness, and assessing the wear condition of accessories.

These data are not only used for real-time problem diagnosis, but also integrated into SBM online equipment operation database, providing an accurate data foundation for future equipment R&D and process optimization.

The More Steadfast the Journey, the Clearer the Vision!Every journey of SBM is a step to consolidate the foundation of China's manufacturing industry and explore its future development. On the new journey of high-quality development, SBM is adhering to its original aspiration with craftsmanship, forging the future with quality, and working hand in hand with customers to jointly write a new chapter in the transformation and upgrading of China's manufacturing industry.

This time, SBM return visit team came to Hebei, an important industrial hub surrounding Beijing and Tianjin, which undertakes the dual mission of the coordinated development of the Beijing-Tianjin-Hebei region and industrial transformation and upgrading. On this land, where the traditional industrial foundation is solid and emerging industries are rising rapidly, SBM advanced powder grinding equipment and technologies are deeply involved, injecting strong impetus into the high-quality development of the region.

Currently, SBM powder grinding equipment has continuously served over 180 countries and regions worldwide. With its stable and efficient product performance and comprehensive after-sales service system, it has become the preferred high-end equipment solution for customers in the powder processing industry at home and abroad.

Recently, the return visit team of SBM After-Sales Service Tour of Grinding Mill arrived as scheduled, launching an in-depth service journey in Hebei and providing solid technical support and service guarantees for the development of local enterprises.

Eight years of continuous return visits have witnessed the leapfrog growth of customer enterprises. Many enterprises that partnered with SBM in the early years have developed from their initial start-up scale into backbone forces in the industry.

A power plant desulfurization enterprise in in-depth cooperation with SBM has three MTW European trapezium grinding mill purchased from SBM. After years of continuous operation, these machines still maintain strong performance, and the return visit inspection shows that the equipment is in excellent condition.

Processed Material: Limestone

Finished Product Fineness: 200 Mesh

Finished Product Application: Steel Plant Desulfurization

Equipment: MTW European trapezium grinding mill

The customer stated, "Choosing SBM means choosing stability and reliability. These devices are not only production tools, but also witnesses and participants in the development of our enterprise."

Processed Material: Calcined Coke

Finished Product Fineness: 200 Mesh

Finished Product Application: New Energy Anode Material

Equipment: MTW European trapezium grinding mill

Focused on quality, aligned in service. SBM engineers consider all aspects for customers: during the inspection, they found slight wear on the grinding rollers, which was within the expected range. Nevertheless, they still formulated a detailed preventive maintenance plan for the customer and trained the customer's employees on equipment maintenance and care measures to ensure the long-term stable operation of the equipment.

Thoughtful service has won unanimous praise from customers: "We are very satisfied with SBM's after-sales service. Any problems are solved in the first place, and it is clear from this annual return visit activity that SBM is a responsible and accountable major brand worthy of trust!"

Processed Material: Limestone

Equipment Used: MTW European trapezium grinding mill

SBM's service goal is to free customers from worries, and various actions are also practicing this concept. "From the punctuality of equipment delivery, to the professionalism of installation and commissioning, and then to the timeliness of after-sales maintenance, SBM has demonstrated strong capabilities in all links," the customer commented on the excellent cooperation results.

These high praises from customers are exactly the original aspiration of SBM's all-round service. With "full-cycle companionship" as the core of its service, SBM covers the entire life cycle of equipment from pre-sales, in-sales to after-sales. This goes beyond the simple attribute of SBM's equipment as a production tool, turning it into a partner that grows together with customers.

SBM After-Sales Service Tour of Grinding Mill is more than just a one-time return visit; it is committed to building a long-term cooperative ecosystem. The return visit team implements a standardized process to provide customers with comprehensive inspection, maintenance and repair services.

Everywhere they go, the engineer team conducts a comprehensive inspection of the equipment, including recording the original equipment operation data, checking the finished product fineness, and assessing the wear condition of accessories.

These data are not only used for real-time problem diagnosis, but also integrated into SBM online equipment operation database, providing an accurate data foundation for future equipment R&D and process optimization.

The More Steadfast the Journey, the Clearer the Vision!Every journey of SBM is a step to consolidate the foundation of China's manufacturing industry and explore its future development. On the new journey of high-quality development, SBM is adhering to its original aspiration with craftsmanship, forging the future with quality, and working hand in hand with customers to jointly write a new chapter in the transformation and upgrading of China's manufacturing industry.

This time, SBM return visit team came to Hebei, an important industrial hub surrounding Beijing and Tianjin, which undertakes the dual mission of the coordinated development of the Beijing-Tianjin-Hebei region and industrial transformation and upgrading. On this land, where the traditional industrial foundation is solid and emerging industries are rising rapidly, SBM advanced powder grinding equipment and technologies are deeply involved, injecting strong impetus into the high-quality development of the region.