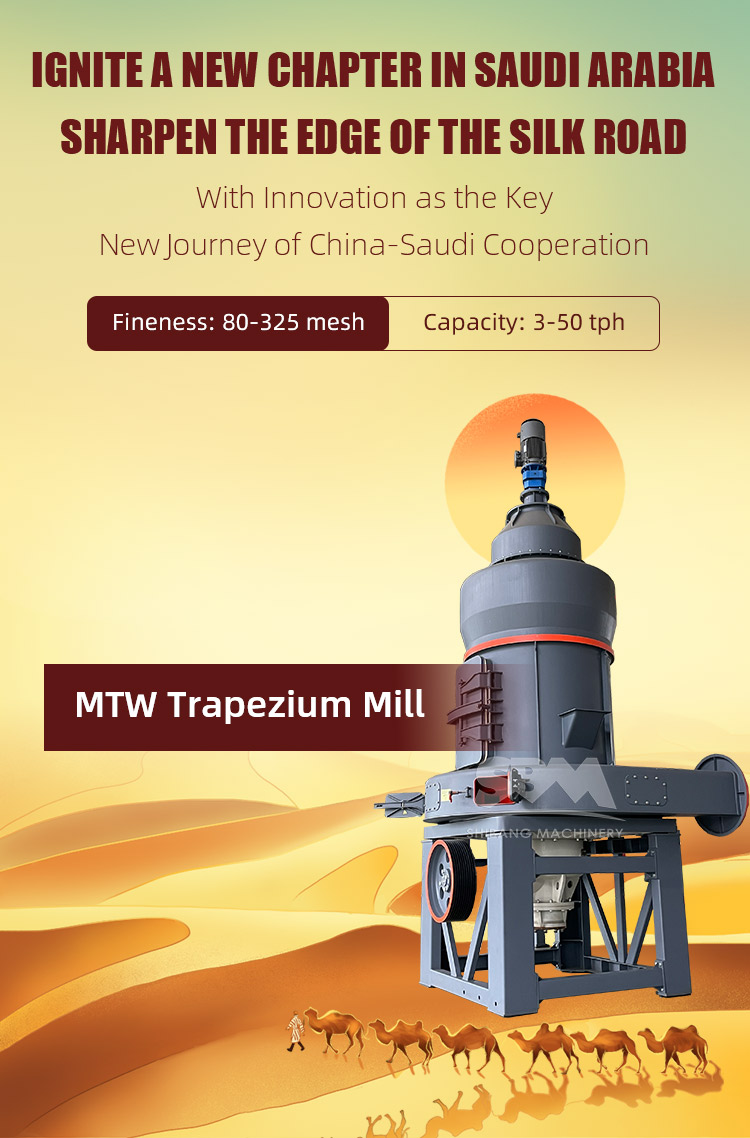

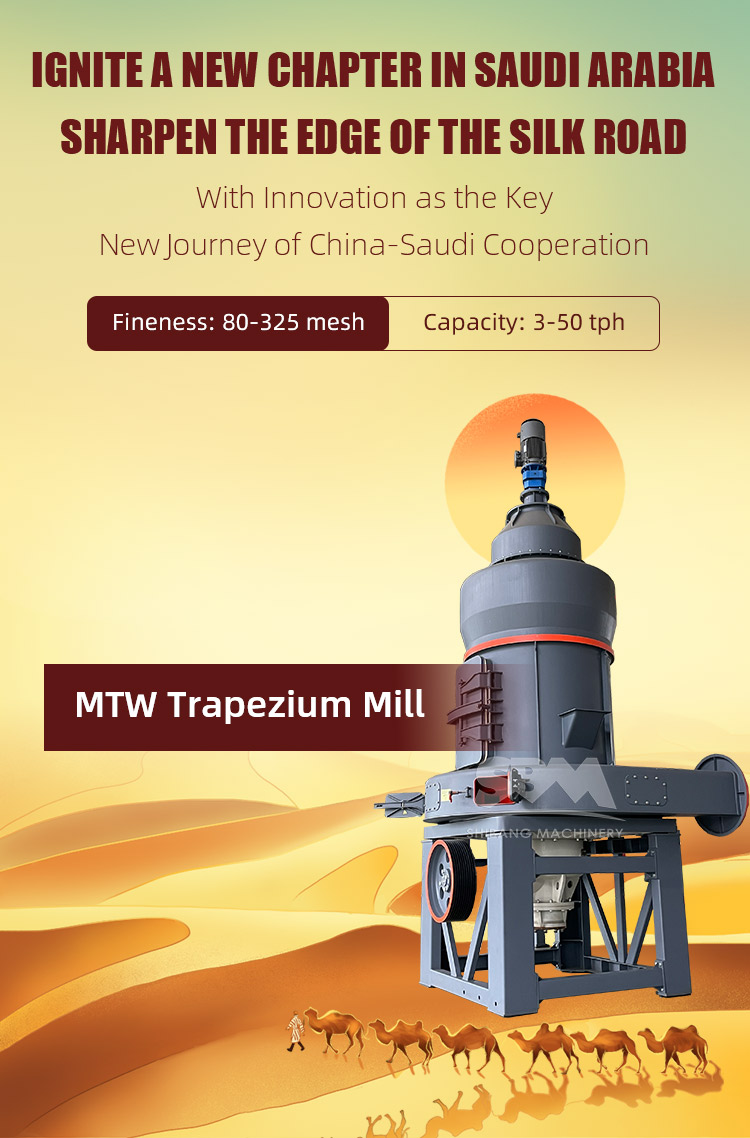

SBM MTW trapezium mill drives upgrades the "desert building materials" to a higher quality

Driven by globalization, the cooperation between Chinese equipment manufacturing enterprises and the Middle East market has become increasingly close. As a global powder grinding equipment manufacturer, SBM has successfully helped a limestone processing project in Saudi Arabia achieve efficient production by relying on its independently developed MTW trapezium mill.

Against the backdrop of globalization, the cooperation between Chinese equipment manufacturing enterprises and the Middle East market has been deepening. As a global powder grinding equipment manufacturer, SBM has successfully supported a limestone processing project in Saudi Arabia to achieve efficient production with its independently developed MTW European trapezium mill.

Saudi Arabia is located in the eastern sedimentary area of the Arabian Shield, boasting abundant limestone reserves but with uneven development levels. In recent years, driven by the local promotion of green upgrading in the construction industry, the fine application scenarios of limestone powder have expanded rapidly.

Against this backdrop, a well-known local building materials group in Saudi Arabia launched a limestone deep processing project, aiming to build a production line with an annual output of 50,000 tons of limestone fine powder with a particle size of 100 mesh.

The project put forward strict requirements for equipment stability, finished product accuracy and energy consumption control. After evaluating and reviewing multiple suppliers, the group finally chose to cooperate with SBM and introduce its star product - the MTW European trapezium mill, using Chinese technology to solve the powder processing challenges in the Middle East.

Material: Limestone

Fineness: 100 mesh

Equipment: MTW European trapezium mill

In response to the special working conditions of "high temperature, heavy dust and high load" in the Saudi project, the technical team of SBM has carried out customized scheme design. The main equipment adopts MTW European trapezium mill, which not only ensures that the pass rate of 100-mesh finished products reaches 98%, but also is more energy-saving than the local traditional Raymond mill.

The core components such as grinding roller bearings are made of wear-resistant materials and lubricated with thin oil, which can operate stably for a long time in a row, perfectly adapting to the production mode of "small batch, high precision and long cycle" of Saudi customers.

Technical Highlights of MTW European trapezium mill

1. Technological Iteration for Mature and Stable Performance

2. Special Grinding Design for High Efficiency

3. Bevel Gear Integral Transmission for Energy Saving

4. Thin Oil Lubrication to Prolong Bearing Life

5. New Frequency Conversion Powder Selector for High-precision Finished Products

Full lifecycle services of SBM in project execution: integrating Chinese equipment manufacturing advantages with local needs in Saudi Arabia:

On-site Installation and Commissioning

A special team of senior engineers was dispatched to the Saudi site, overcoming challenges such as high temperatures, language barriers, and cultural differences. Accomplished equipment positioning, pipeline docking, and electrical debugging within a short period, ensuring rapid project implementation.

Interactive Technical Training

An integrated training system of "theoretical lectures + practical drills" is adopted. The training content covers the operation of intelligent central control systems, replacement procedures for vulnerable parts, and fault diagnosis, ensuring that the operation team has the independent disposal capability.

Localized Service Network

A localized sales and service system has been established. Whether in equipment installation and debugging, technical training, or daily maintenance and troubleshooting, SBM can quickly provide customers with professional and efficient technical support.

The production director of the client stated: "SBM grinding mill not only features reliable performance and simple operation and maintenance, but its service support has eliminated our worries, and more importantly, provided strong guarantee for our participation in local major engineering projects." The successful implementation of the project not only demonstrates to the world SBM core technical strength in the field of non-metal mineral powder processing, but also provides key support for Saudi Arabia's infrastructure construction and industrial raw material upgrading with the precise services of "Smart Manufacturing in China".

Against the backdrop of globalization, the cooperation between Chinese equipment manufacturing enterprises and the Middle East market has been deepening. As a global powder grinding equipment manufacturer, SBM has successfully supported a limestone processing project in Saudi Arabia to achieve efficient production with its independently developed MTW European trapezium mill.

Saudi Arabia is located in the eastern sedimentary area of the Arabian Shield, boasting abundant limestone reserves but with uneven development levels. In recent years, driven by the local promotion of green upgrading in the construction industry, the fine application scenarios of limestone powder have expanded rapidly.

Against this backdrop, a well-known local building materials group in Saudi Arabia launched a limestone deep processing project, aiming to build a production line with an annual output of 50,000 tons of limestone fine powder with a particle size of 100 mesh.

The project put forward strict requirements for equipment stability, finished product accuracy and energy consumption control. After evaluating and reviewing multiple suppliers, the group finally chose to cooperate with SBM and introduce its star product - the MTW European trapezium mill, using Chinese technology to solve the powder processing challenges in the Middle East.

Material: Limestone

Fineness: 100 mesh

Equipment: MTW European trapezium mill

In response to the special working conditions of "high temperature, heavy dust and high load" in the Saudi project, the technical team of SBM has carried out customized scheme design. The main equipment adopts MTW European trapezium mill, which not only ensures that the pass rate of 100-mesh finished products reaches 98%, but also is more energy-saving than the local traditional Raymond mill.

The core components such as grinding roller bearings are made of wear-resistant materials and lubricated with thin oil, which can operate stably for a long time in a row, perfectly adapting to the production mode of "small batch, high precision and long cycle" of Saudi customers.

Technical Highlights of MTW European trapezium mill

1. Technological Iteration for Mature and Stable Performance

2. Special Grinding Design for High Efficiency

3. Bevel Gear Integral Transmission for Energy Saving

4. Thin Oil Lubrication to Prolong Bearing Life

5. New Frequency Conversion Powder Selector for High-precision Finished Products

Full lifecycle services of SBM in project execution: integrating Chinese equipment manufacturing advantages with local needs in Saudi Arabia:

On-site Installation and Commissioning

A special team of senior engineers was dispatched to the Saudi site, overcoming challenges such as high temperatures, language barriers, and cultural differences. Accomplished equipment positioning, pipeline docking, and electrical debugging within a short period, ensuring rapid project implementation.

Interactive Technical Training

An integrated training system of "theoretical lectures + practical drills" is adopted. The training content covers the operation of intelligent central control systems, replacement procedures for vulnerable parts, and fault diagnosis, ensuring that the operation team has the independent disposal capability.

Localized Service Network

A localized sales and service system has been established. Whether in equipment installation and debugging, technical training, or daily maintenance and troubleshooting, SBM can quickly provide customers with professional and efficient technical support.

The production director of the client stated: "SBM grinding mill not only features reliable performance and simple operation and maintenance, but its service support has eliminated our worries, and more importantly, provided strong guarantee for our participation in local major engineering projects." The successful implementation of the project not only demonstrates to the world SBM core technical strength in the field of non-metal mineral powder processing, but also provides key support for Saudi Arabia's infrastructure construction and industrial raw material upgrading with the precise services of "Smart Manufacturing in China".