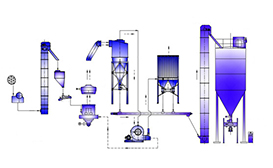

Pulverized coal

Introduction

Particle properties of pulverized coal are made of different sizes, irregularly shaped particles composed of flour, generally pulverized coal particle diameter range 0-1000um, most of the particles 20-50um; the less dense pulverized coal density, new polished pulverized coal bulk density had about (0.45-0.5) t / m3, stored after a certain time a bulk density (0.8-0.9) t / m3; pulverized coal particles having fluidity very fine, per unit mass of pulverized coal with more large surface area, the surface can absorb a lot of air, so that it has fluidity. This feature enables easy pneumatic conveying of pulverized coal, pulverized coal gravity disadvantage is easy to form and easy to leakage of powder when the device is not tight.