Maintenance Tips to Keep Your Ultrafine Vertical Mill Efficient

Ultrafine vertical mill has been widely used in raw material crushing in several basic industries such as mining, metallurgy, building materials, chemical industry, and power sector. With the development of the ceramic industry, ball mills have also become indispensable mechanical equipment in the grinding process of the ceramic industry.

In the long run, vertical roller mill will continue to be the main equipment for raw material grinding in the ceramic industry for a considerable period of time in the future. Therefore, the research on vertical mills has also received high attention from relevant experts, and in recent years, many achievements have been made both domestically and internationally.

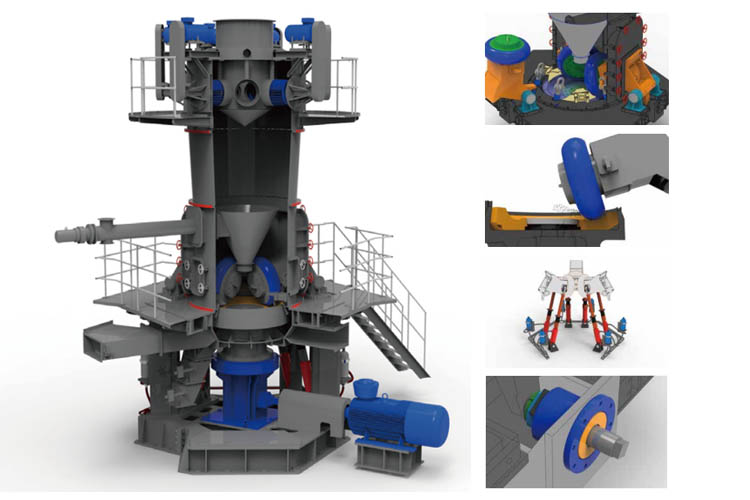

Ultrafine vertical mill is an important equipment in modern industrial production, and its operation directly affects production efficiency and product quality. In order to ensure the stability and safety of the equipment, daily maintenance work is very important. Below, we will share some tips on daily maintenance of ultrafine vertical mill, so that you can easily improve their lifespan.

Here are some maintenance tips to keep your ultrafine vertical mill efficient:

1. Regular Lubrication

The most important aspect of any machinery is proper lubrication. Regular lubrication of the bearings, gears, and other moving parts can significantly reduce friction and wear, leading to improved efficiency and longer lifespan of the machine. Make sure to follow the manufacturer's recommendations for lubrication intervals and use the recommended lubricant.

2. Routine Inspection

Regular inspection of the machine can help detect any potential issues before they turn into major problems. Check for any signs of wear and tear, loose or damaged parts, and abnormal sounds or vibrations. Replace or repair any damaged parts immediately.

3. Cleanliness

Keeping the machine clean is essential for its efficient operation. Dust, debris, and other contaminants can clog the machine, reducing airflow and causing overheating. Clean the machine regularly using a vacuum or compressed air.

4. Proper Operating Procedures

Make sure to follow the manufacturer's operating procedures to avoid any unnecessary stress on the machine. Avoid overloading the machine, and make sure to use the correct feed rate and cutting speed.

5. Training and Education

Proper training and education of the machine operator can go a long way in ensuring the efficient operation of the machine. Make sure the operator is trained to operate the machine correctly and safely, and is aware of any potential hazards.

By following these maintenance tips, you can help ensure the efficient operation of your ultrafine vertical mill and extend its lifespan.