7 Key Differences Between Raymond Mill And Vertical Roller Mill

Raymond Mill and Vertical Roller Mill are two types of grinding mills commonly used in the field of industrial grinding.

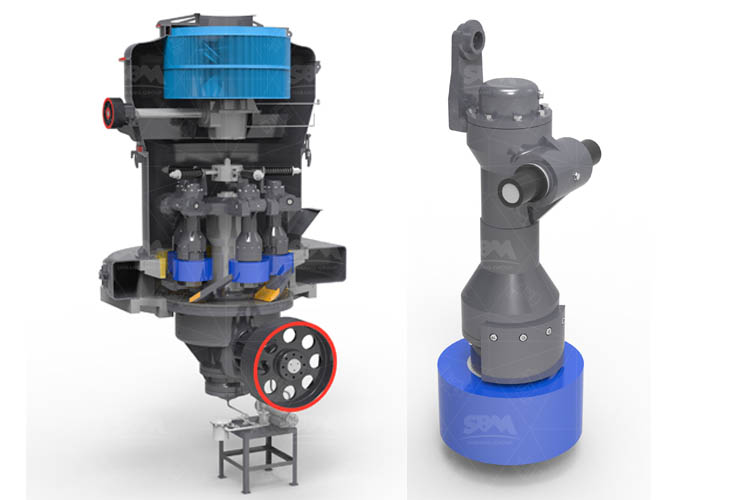

What is a Raymond Mill?

Raymond Mill, also known as Raymond Roller Mill, is a widely used grinding mill. It consists of a rotating grinding ring with multiple grinding rollers suspended in a housing. The material to be ground is fed into the grinding chamber between the grinding roller and the grinding ring, and it is crushed and ground by the rolling action of the grinding rollers. The finished powder is collected and discharged through a classifier. Raymond Mill is known for its high efficiency, low energy consumption, and relatively low maintenance requirements. It is suitable for grinding various non-flammable and non-explosive materials with Mohs hardness below 9.3 and humidity below 6%.

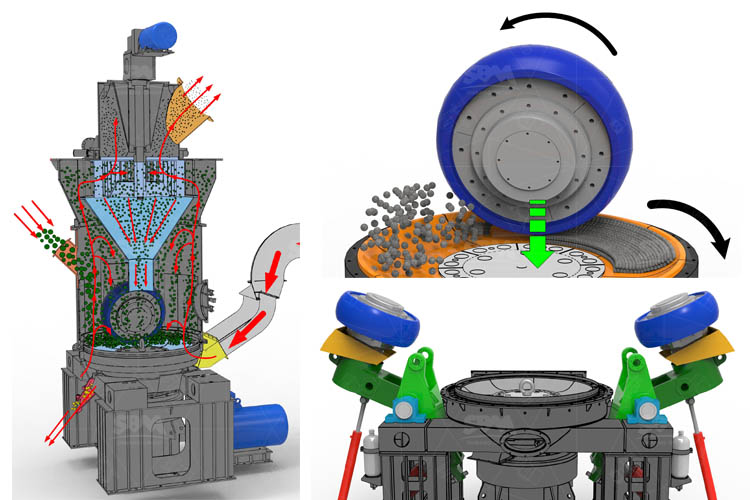

What is a Vertical Roller Mill?

Vertical Roller Mill, also known as VRM, is a grinding mill that uses a vertically oriented grinding roller and a grinding table to crush and grind the material. The material is fed into the mill through a central inlet at the top and is thrown outward by centrifugal force under the action of the grinding roller. The crushed material is carried by the air stream to the separator, where the coarse particles are separated and returned to the grinding table for further grinding, while the fine particles are collected as the final product. Vertical Roller Mill is widely used in various industries such as cement, power generation, metallurgy, chemical industry, and more. It offers advantages such as high grinding efficiency, low power consumption, and the ability to dry, grind, and classify materials simultaneously.

Raymond Mill VS Vertical Roller Mill

Both Raymond Mill and Vertical Roller Mill have their own advantages and are suitable for different grinding applications. But there are also some differences between them, knowing clearly will help you choose the right grinding mill.

Here are 7 key differences between Raymond Mill and Vertical Roller Mill:

1. Working Principle

Raymond Mill: The Raymond mill operates mainly underneath the power of affecting and grinding. The motion of Raymond mill obtainable inside the cylinder total body takes many diverse types. Some media make upward motion by affixing for the section of the cylinder.

Vertical Roller Mill: The Vertical Roller Mill, by contrast, is characterized by its vertical grinding rollers. The material is ground between the grinding rollers and the grinding table. The force for milling is created through the rotation of the grinding table.

2. Structure

Raymond Mill: Generally Raymond mills combine the main body, air blower, powder collector, dust filter and other components. It's a relatively compact structure.

Vertical Roller Mill: Vertical Roller Mills typically include more components such as a separator, roller, disc, pressure device, reducer, motor, shell and other components.

3. Input Size

Raymond Mill: Raymond mill can handle a relatively coarse feed size of around 30mm.

Vertical Roller Mill: Vertical Roller Mills can handle a much finer feed, typically up to a few millimeters or less.

4. Output Size

Raymond Mill: Raymond mills usually have a finished particle size range of 0.044-0.165 mm, a small number of materials can reach 0.013 mm (1000 mesh).

Vertical Roller Mill: Vertical Roller Mills, on the other hand, can produce a finished product particle size of less than 20μm.

5. Efficiency

Raymond Mill: Raymond mill has a long history and is widely used for small and medium-sized mills. However, its efficiency is not high, and it needs more space.

Vertical Roller Mill: Vertical Roller Mill technology matures, and its efficiency is higher than Raymond mill. It occupies a small area, is open-air and has a strong adaptability to the environment.

6. Wear and Tear

Raymond Mill: The grinding part of the Raymond mill is a grinding roller and a grinding ring. During the processing of the material, the grinding roller is in close contact with the grinding ring, which often leads to wear and tear.

Vertical Roller Mill: The grinding parts of a Vertical Roller Mill are the grinding roller and the grinding table. Because there is no direct contact and impact between the grinding roller and the millstone, the wear is small and the service life is long.

7. Applications

Raymond Mill: Raymond mill is more suitable for processing small and medium-sized materials with a hardness of 7 or less.

Vertical Roller Mill: Vertical Roller Mill can process materials with hardness of less than Mohs 7, but it is more suitable for processing large-scale materials due to its high production capacity.

It's important to note that the appropriate choice between a Raymond mill and a Vertical Roller Mill depends on the specific needs of your project, including the types of materials you're working with and the desired final product size.