Gypsum Powder Production in Ethiopia

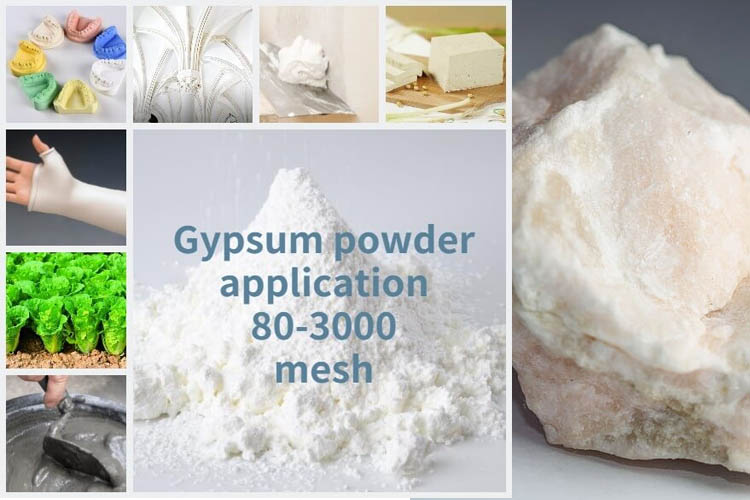

Ethiopia has abundant gypsum resources, and the country has been actively developing its gypsum industry in recent years, establishing many gypsum powder factory in ethiopia. Gypsum, a mineral widely used in various industries, is processed into powder form for applications such as construction materials, cement production, agriculture, and more.

Gypsum Powder Manufacturing Process

The process of gypsum production in Ethiopia involves several stages:

1. Mining: Gypsum deposits are identified through geological surveys. Once located, the gypsum rock is extracted from mines using methods like drilling and blasting.

2. Crushing: The mined gypsum ore is crushed into smaller fragments to facilitate further processing. Crushing equipment such as jaw crushers or impact crushers may be used for this purpose.

3. Grinding: The crushed gypsum is then ground into a fine powder in a grinding mill. Various types of grinding mills can be used for grinding, including ball mills, Raymond mills, ultrafine vertical mills, and vertical roller mills. The grinding process reduces the gypsum ore to the desired fineness.

4. Calcination: The ground gypsum powder is subjected to calcination in a rotary kiln or calciner. Calcination is a process that involves heating the gypsum powder at high temperatures to remove the water of crystallization and convert it into a hemihydrate form known as plaster of Paris. The calcination process results in the formation of gypsum plaster, which is a key ingredient in various construction materials.

5. Drying and Packaging: The calcined gypsum plaster is then dried to remove any remaining moisture. After drying, the gypsum powder is packaged into bags or other containers for distribution and sale.

Gypsum Powder Production in Ethiopia Opportunities and Challenges

The development of gypsum powder plant in Ethiopia has contributed to the country's economic growth, job creation, and the expansion of its construction industry. It has also helped meet the local demand for gypsum-based products and reduced the need for imports.

Here are some aspects related to gypsum powder production in Ethiopia:

1. Resources and Mining: Ethiopia has an abundant reserve of gypsum, particularly in the Tigray, Amhara, and Afar regions. The mining of gypsum has been on the rise with the surge in construction activities, and local supply often meets the demand.

2. Manufacturing and Processing: There are several gypsum factories in Ethiopia that produce gypsum board and gypsum plaster. With modern technology, these factories are able to produce high-quality products that meet international standards.

3. Domestic Consumption: With the rapid urbanization and the government's efforts in building infrastructure and housing projects, the demand for gypsum products like plaster, board, and blocks has seen a significant increase in the country.

4. Challenges: Like many sectors in Ethiopia, the gypsum industry faces challenges such as:

Energy Issues: Irregular electricity supply can hamper production.

Transportation: Inefficient road networks can make transportation of raw material and finished goods challenging.

Quality Consistency: Ensuring consistent quality of the gypsum powder can sometimes be a challenge, especially for smaller producers.

Limited Skilled Labor: The industry often faces a shortage of skilled labor, which can affect production quality and efficiency.

5. Opportunities: Given the rich gypsum deposits and the increasing demand for construction materials, there's substantial potential for growth in the gypsum industry in Ethiopia. Foreign investments and partnerships can further bolster this potential by introducing advanced technologies, improved practices, and capacity-building initiatives.

6. Exports: Although the majority of the gypsum products cater to the domestic market, there's a potential for exporting to neighboring countries if production capacity and quality standards can be ramped up.

7. Environmental Considerations: As with any mining and production activity, care must be taken to ensure that environmental impacts are minimized. This includes responsible mining practices, efficient use of resources, and proper waste management.

In summary, while Ethiopia has abundant gypsum resources and a growing demand, there are challenges that need to be addressed to fully realize the potential of the sector. Strategic investments, capacity building, and a focus on sustainable practices could position Ethiopia as a significant player in the gypsum industry in the region.