Product Overview

MB5X Pendulous Hanging Grinding Mill represents the most advanced grinding processing technology. The brand-new structural design not only lowers the operation and maintenance cost, but also does well in environmental protection and finished product quality. It is available when processing the non-combustible, non-explosive brittle minerals products like limestone, calcite and marble, etc. MB5X Pendulum mill is widely used in mining, building, power plant and coating industries.

Scope Of Application

Mining Industry

Building Industry

Power Plant Industry

Coating Industry

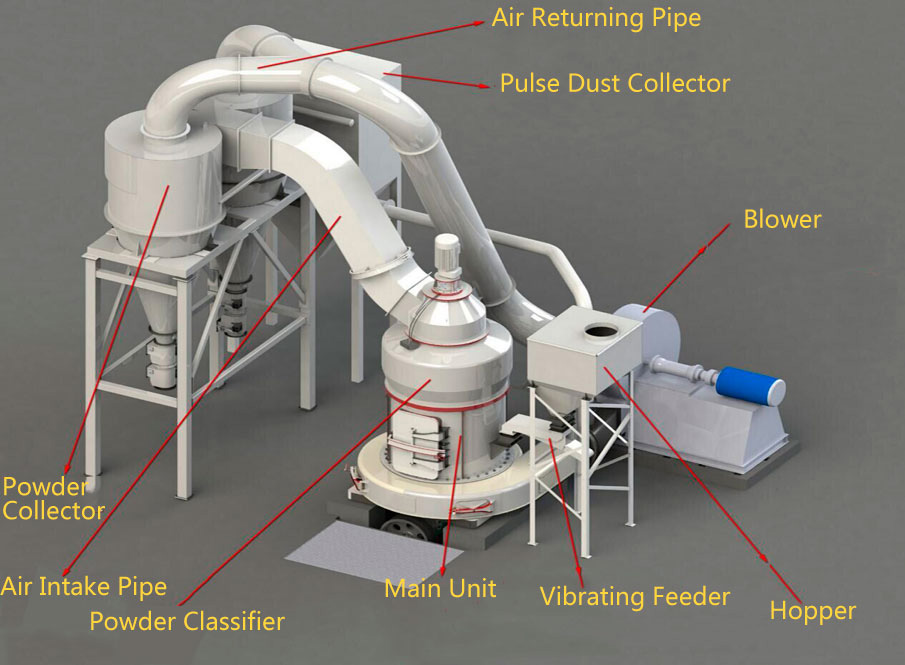

Introduction To Complete Machine Structure And Working Process

After being crushed into the little particles whose sizes are permissible for the MB5X Pendulum Mill, the crushed materials are then sent into hopper.

Crushed materials are evenly and continuously fed into the grinding cavity at fixed quantity for grinding by vibrating feeder.

The qualified pulverized powder enters into the powder collector for storage under the action of blower.

Finally finished powders are discharged through the discharging hole.

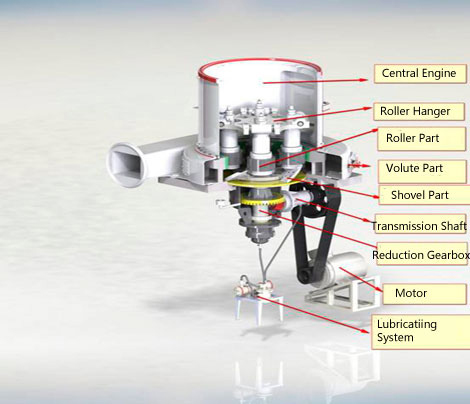

Introduction To Main Unit Structure And Working Process

- central engine

- roller hanger

- roller part

- volute part

- shovel part

- transmission shaft

- reduction gearbox

- motor

- lubricatiing system

Main unit’s working process

As for the working process of each main unit, the roller part is the key in pulverization. By rotating, the materials can be ground into powder with ideal and expected size. The rollers of MB5X Pendulum Mill take thin oil lubricating device which operates automatically. It works with rollers synchronously to help lubricate rollers and disperse heat. Below the rollers, shovel plate is installed. In the process of pulverizing, the shovel plate would rotate with the grinding rollers at the same time and play an important part in throwing up materials to feed them into grinding roller rings so as to form a padding layer. The padding layer is then ground into powder under action of outward centrifugal force generated by grinding rollers. The roller hanger of MB5X Mill uses the mesh-typed design which ensures the ventilation area in grinding cavity and material conveying efficiency so that the whole grinding efficiency is elevated.

Technical Advantage

Excellent Stability

Diluted oil lubricating method is fully automatic and labor-saving. Man-free operation ensures stability.

High Grinding Efficiency

The structure of special groove shovel flow channel concentrates materials effectively, increasing grinding efficiency.

High Material-conveying Efficiency

Grinding roller hanger applies unique mesh design which increases ventilation area without changing hanger strength so as to improve material-conveying efficiency.

Low Power Consumption

New-typed cage powder concentrator makes power consumption of the system less.

Long Service Life

Humanized design avoids frequent manual maintenance and extends the service life.

Environment-friendly Design

Installation of pulse dust collector removes ash via pneumatic force to help avoid powder pollution.

Main Technical Parameters

NOTE:Capacity is according to the medium hard limestone.The size,humidity level and characters of matericalswill influence the capacity.

Contact us

Fill your requirements on the following form, we will contact you as soon as possible.