Magnesium Desulfurization Technology

Magnesium Desulfurization & Its Advantages

Magnesium desulfurization refers that after the magnesite is calcined, the resultant--- magnesium oxide as desulfurization absorbent would be produced by seriflux production system into magnesium hydroxide which is then fully mixed with smoke in desulfurization absorbing tower. The sulfur dioxide in the smoke would react with magnesium hydroxide to form magnesium sulfite to clean coal smoke by removing some acid materials like SO2, SO3, HCl, HF contained in the coal smoke. Magnesium desulfurization has many advantages.

-

Low investment

The desulfurization projects occupy a few floor areas. The investment is lower.

-

Stable operation

The desulfurization process is stable. It is free from some problems like blocking.

-

Environment friendly

It hardly produces something bad for the environment.

-

Recycled by-products

The by-products can be used again in avoidance of unnecessary wasting.

-

Promising economic benefits

The magnesium desulfurization is profitable because the desulfurizing agents can be used repeatedly which lowers the desulfurization costs so as to increase economic profits.

Wastewater Processing System of Magnesium Flue Gas Desulfurization(FGD)

Because the Magnesium Flue Gas Desulfurization(FGD) usually takes the fully-close water circulation mode and waste water mainly comes from the desulfurizing process, many metallic elements would concentrate within the desulfurization device, exerting a negative on it. So hereinafter the wastewater processing system would be discussed specially.

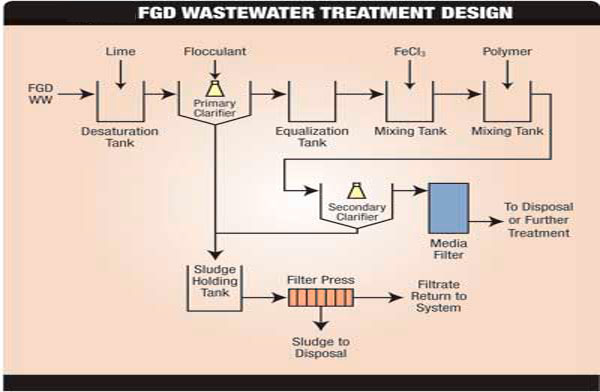

The wastewater processing system is divided into three parts, namely: wastewater treatment systems, sludge dewatering system, chemical dosing system.

1. Wastewater treatment system

Firstly, wastewater enters into grille wells where suspended solids and floating debris are separated. And then by the lift pump, it enters into the neutralization pool in which pH value of the wastewater is adjusted to be neutral, and here lime milk is fully mixed with wastewater whose components like SO42-, SO32- and F- are fully reacted with Mg2 + to form insoluble MgSO3 etc. After the reaction, the wastewater enters into the reaction tank in which flocculant is put. Under the action of flocculant, coarse floc is formed and enters into the sedimentation tank for solid-liquid separation that the supernatant flows into the collection well and is then pumped into the sand filter. After filtration, it goes into clean water reservoir. On-line detection instrument, installed on the filter outlet pipe, can monitor pH, suspended solids, and COD real-timely.

2. Sludge dewatering system

Before sedimentation and discharge of sewage, it should be condensed first. After that, the supernatant flows back to the grid pool. Sludge on the clarifier is discharged by screw pump sludge. Part of it flows back to the neutralization box to offer crystal nucleus to add sludge concentration within neutralization box. Rest of sludge is sent by screw pump into pressure filter for dehydration.

3. Chemical Dosing System

Chemical dosing system includes: hydrochloric acid adding device (controlling the pH value between 6-9, and cleaning pH electrode regularly); complex iron adding device; organic sulfur adding device; coagulant adding device; lime adding device. All units are equipped with low liquid level alarm.

Technological Process

The slurry discharged from the desulfurization tower contains 15% solids whose main component is magnesium sulfite. The effluent slurry must be dewatered for further processing to obtain the desired by-product. In this project, the dewatering system comprises a dewatering supply tank, a dewatering supply pump, a centrifugal dewatering machine, a dryer and other related equipment.

The desulfurizing slurry in the desulfurizing tower is sent to the dehydration supply tank through the slurry discharging pump, and then the concentrated desulfurization by-product is conveyed to the hot air drier by the screw conveyor. By-products about 10% moisture flow back to storage bin. In the whole process only qualified wastewater processed can be discharged. The desulfurization wastewater treatment process: neutralization, sedimentation, flocculation, clarification.

Effect Analysis

The discharged water processed by wastewater processing system can reach the first-class emission standards for second class of pollutants in the maximum allowable emission concentration according to the national "Integrated Wastewater Discharge Standard" GB8978-1996. The sampling and analysis of water are carried out in accordance with GB [1 ,2]. Sewage treatment station can lead annual 75t reduction of SS emissions.

| order | Item | Before Processing | After Processing | Standard | Results |

| 1 | PH | 2-3 | 6-9 | 6-9 | eligible |

| 2 | Temp.(℃) | 49 | Normal temperature | eligible | |

| 3 | CODcr,mg/L | 250 | <100 | 100 | eligible |

| 4 | SS,mg/L | 5900 | <70 | 70 | eligible |

| 5 | SO42-,mg/L | <10000 | <1.0 | <1.0 | eligible |

| 6 | Cl-,mg/L | 10000 | <1.0 | 1 | eligible |

| 7 | F-,MG/L | 1000 | <10 | 10 | eligible |