Talc

Barite

Calcite

Dolomite

Marble

Kaolin

Wollastonite

Gypsum

Limestone

Pyrophillite

Feldspar

LUM Series Ultrafine Vertical Grinding Mill is designed on the basis of years of grinding mill production experience. It adopts the Taiwanese grinding roller technology and German powder separating technology. The ultrafine vertical grinding mill integrates ultrafine powder grinding, grading, powder collecting and transporting.

As the dedicated mid-to-high end processing equipment in plastic masterbatches, PVC, artificial stone, electric cable, non-woven fabrics and other industries, LUM Series Ultrafine Vertical Grinding Mill is mainly used for the ultrafine grinding of calcite, marble, limestone, talc, dolomite, barite, kaolin, wollastonite, gypsum, feldspar, pyrophylite and other non-metallic mineral ores.

Paper Making

PVC

Painting

Plastics

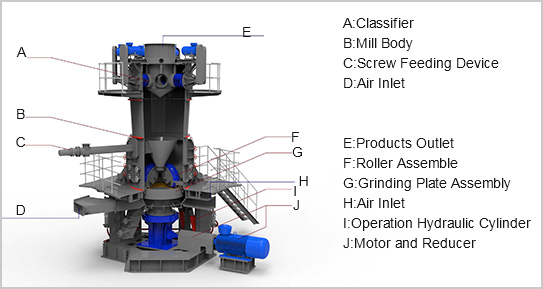

LUM Ultrafine Vertical Grinding Mill is mainly composed of motor, reducer, body, roller, grinding disc, pressure device, powder concentrator, lubrication station and hydraulic station.

(1) Roller and millstone adopt imported wear-resistant material, making them have long service life and low maintenance cost.

(2) The grinding area between roller and millstone adopts unique grinding curve, ensuring the stable operation and efficient grinding.

(3) Hydraulic rod with adjustable elasticity coefficient is used to increase the pressure on the roller, ensuring the continuous grinding pressure on the raw material.

(4) LUM Ultrafine Vertical Grinding Mill adopts mechanical position-limiting device, so that there is no direct contact point between grinding roller and millstone, which can avoid the destructive impact caused by machine vibration.

(5) Multi-rotor cage-type powder concentrator has high efficiency. It’s easy to be adjusted and controlled, which is helpful to achieve the fast switch among different production demands. Therefore, the efficiency of the whole production line can get improved.

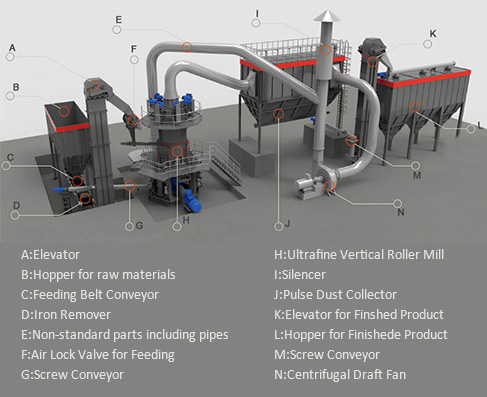

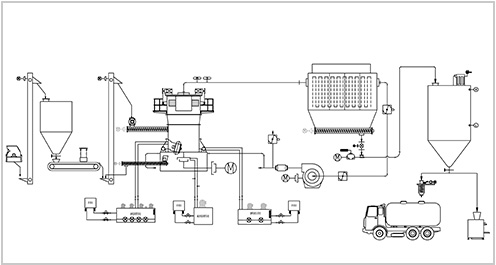

(1) Primary Milling System

This system mainly consists of crushers, conveyors of raw materials, ultrafine grinding and classifying devices, powder collectors, conveyors of finished products and other auxiliary equipment.

Crushing equipment: jaw crusher, hammer crusher etc.

Conveying equipment of raw materials: elevator, belt scale, surge bin, star-shaped feeding valve, spiral conveyer etc.

Ultrafine grinding and grading devices: main machine and multi-rotor classifier of ultrafine vertical grinding mill.

Transportation devices of finished products: spiral conveyer, discharge valve, elevator or pneumatic transport system etc.

Storage bin: final product tank

Auxiliary equipment: grinding aid additive system, cooling water system, compressed air system, iron separator etc.

(2) Secondary Classifying System

The system mainly consists of multi-rotor ultrafine classifier, fan, pulse filter, elevator, discharge valve, spiral conveyer and final product tank etc.

The millstone rotates under the action of main motor and reducer. After being weighed on the belt scale, raw materials, along with the elevator, spiral conveyer, star-shaped feeding valve and feed screw, fall on the center of millstone and next they move to the edge of millstone under centrifugal force. While passing through the grinding area between roller and millstone, raw materials will be pulverized by the pressure of roller and the shearing force between roller and millstone. Raw materials after grinding continue moving to the edge of millstone until they are brought into multi-rotor powder concentrator by the airflow of the high-pressure fan. Powders which fail to meet requirement of fineness fall on the millstone for re-grinding while the ones meeting the requirements enter the dust collector along with airflow, and are then transported to product bin by elevator or pneumatic transport system.

1. Final products boast size diversity and high added value

The main machine is equipped with high-efficiency multi-rotor powder concentrator, so that the final products can have multiple sizes. Content of 2μm of powder can reach as high as 70%. The screen rate of particles whose sizes are within 4—45μm can reach 97%. The specific surface area is around 21000cm^2/g. The discharging rate of 8.5μm of powder can reach 97%. Through secondary powder collection, 4-5μm of powder can be separated. The particle size distribution of finished powder is narrow, and the content of 2μm of powder can be adjusted. And the finished powder has fine shape, making it have high added value.

2. Higher grinding efficiency, lower power consumption

The optimized roller, millstone and inner airflow guidance design greatly improve the grinding efficiency. The capacity of LUM ultrafine vertical grinding mill is 30% higher than similar products and the power consumption is 30%-60% lower than ball mill.

3. Intelligent control system makes operation more stable and efficient

The internal part adopts PLC automatic control system while the external part adopts touch screen so as to display and adjust the parameters in real time. The reserved modular interface has strong expansibility, which can quickly realize the connection between front-end grinding aid adding system and back-end powder modification system and packaging system, ensuring the automatic control of the whole process.

4. Long service life, low maintenance cost

All the wear-resistant parts of main machine adopt imported wear-resistant material, which effectively prolongs their service life and reduces the iron content in the products and decreases the maintenance costs.

5. Environment friendly

With new structural designs and grinding principle, LUM Series Ultrafine Vertical Grinding Mill has small vibration and low noise. The equipment is sealed as a whole and works under negative pressure. All the dust points are controlled by pulse dust filter, so there is no dust overflow, meeting the national environmental protection requirements.

Model/ item |

Characteristics of final products |

Equipment’s performances |

Pendulum grinding mill |

Powder of 2μm takes over above 6%. The fineness can reach 45μm. Low-end finished powder |

Suitable for production of coarse powder and some fine powder above 45μm; Stable, cost-effective, large noise; |

Hoop-roller grinding mill |

Powder of 2μm takes over above 20%. The finest powder can reach to 8-10μm. Mid-to-high end finished powder; |

Suitable for production of powder within 10-15μm; Stable, short service life of quick-wear parts, large noise, low production capacity; |

Ball mill |

Generally used for producing powder coarser than 45μm; ultrafine ball mill can produce powder finer than 10μm; Ceramic ball mill can produce powder with high fineness and whiteness and low iron content; Good particle size, globular shape; |

Suitable for various raw materials; Finished powder has wide particle size range; Many selections of grinding medium; High power consumption, large noise; Long switch time for different production demands; Difficult to adjust fineness; |

Jet grinding mill |

Suitable for producing powder finer than 5μm; Grinding materials under airflow force; finished powder has best whiteness; Suitable for production of high-end edible finished powder; |

Mechanical grinding; powder fineness is high; Only suitable for producing high-end or high added value powder; High power consumption, low production capacity; |

Ultrafine vertical grinding mill |

Powder of 2μm takes over 30%-70%; D97=4-45μm The fineness can reach 8.5μm after primary grinding; High specific surface area; |

No contact between roller and millstone; small vibration, stable operation; Low power consumption, large capacity; Fast switch among different production demands; Products are highly specialized; Large upfront investment; |

Project Address: Hubei, China

Material: Calcite

Capacity: 80000TPY

Input Size: Below 10mm

Output Size: 600-800mesh

Daily Operation: 10h

Equipment: LUM1125 Ultrafine Vertical Grinding Mill

If you would like to get help immediately, PLS click the LIVE-CHAT. Meanwhile, you can also fill your requirements in the following form and we will contact you as soon as possible.